High-Efficiency Turning on Dual-Spindle CNC Lathes, DONGS CNC Global Solutions

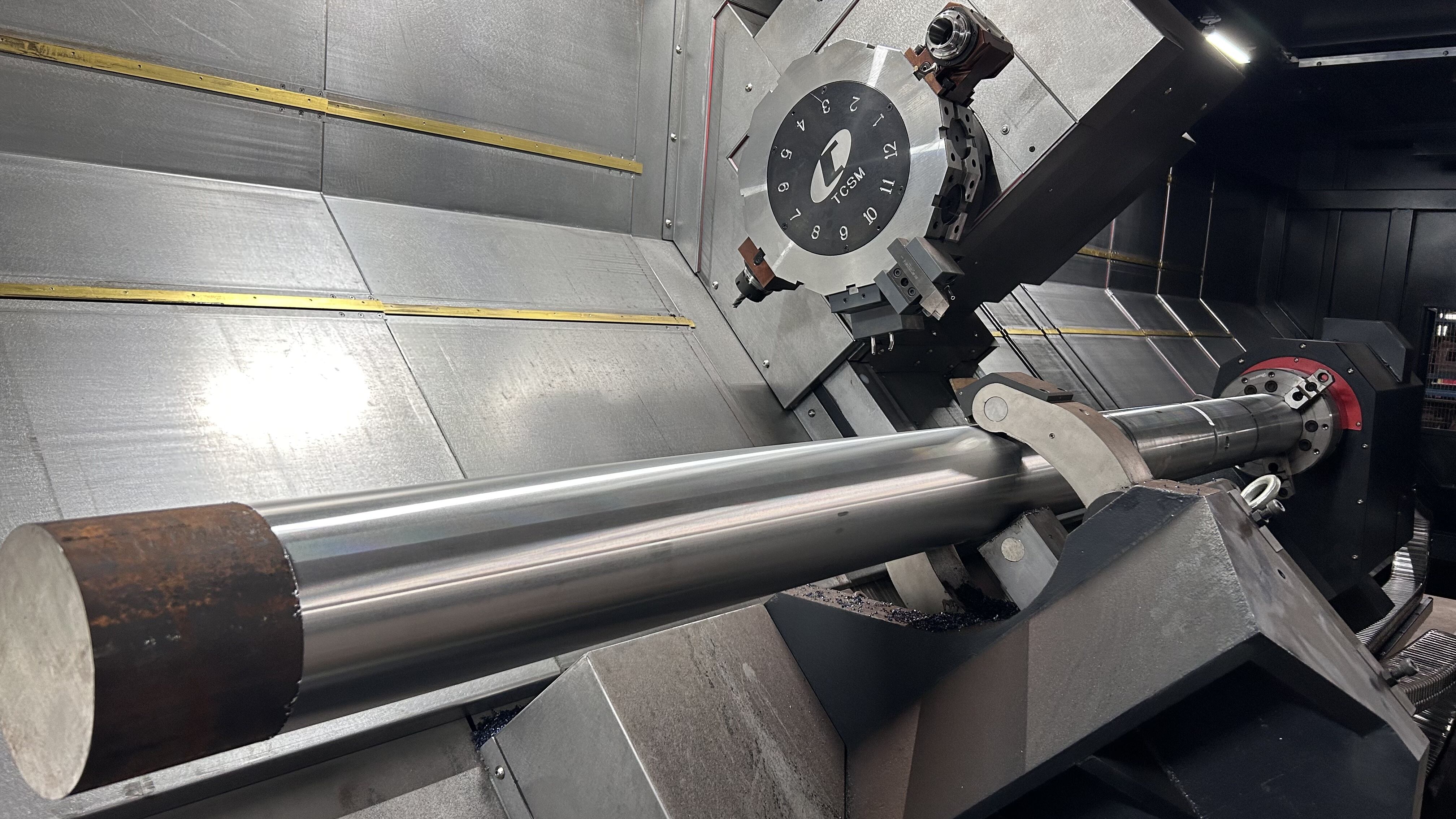

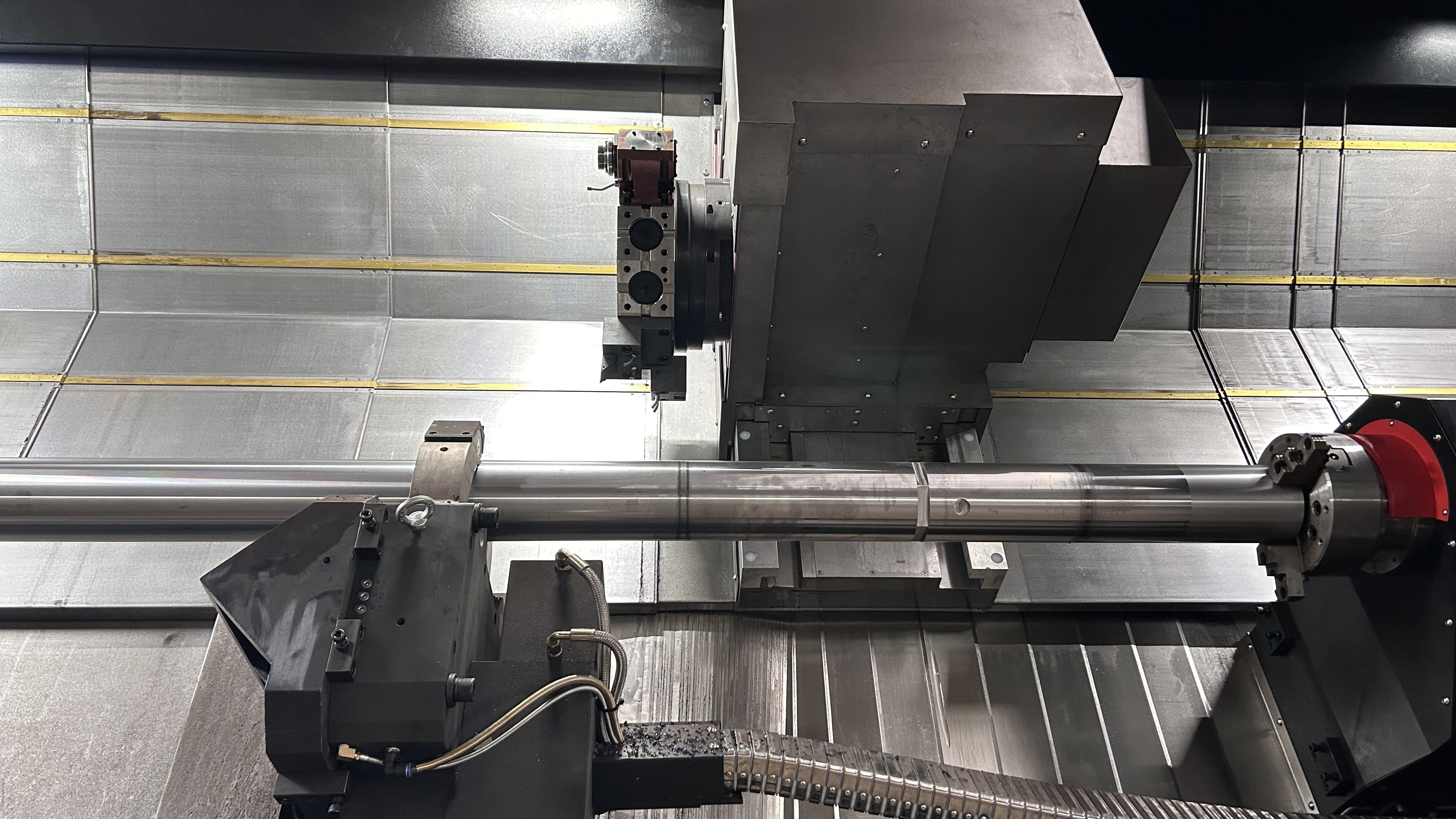

In today's highly competitive manufacturing industry, the pursuit of efficiency and precision represents the most critical concern for the global machining sector. The dual spindle CNC lathe emerges as an efficient machining solution, embodying a paradigm shift in turning methodologies. At the core of the dual spindle lathe is the integration of two independent spindles within a single machine. Typically arranged in an opposing configuration, the primary spindle completes initial machining on one end of the workpiece, after which the secondary spindle immediately begins machining the opposite end by directly receiving or gripping the part. This seamless "handover" process is key to achieving exceptional efficiency. By enabling synchronous machining operations on a single platform and eliminating time spent on workpiece unloading and repositioning, parts can be fully completed in a single setup, significantly boosting production efficiency.

The tokarka cnc dwuwrzecionowa has earned strong endorsement from our Polish partners, where it has become a bestselling model renowned for its proven capabilities (feedback from Polish partners).

From the automotive industry to aerospace, it provides an ideal solution for shaft and disc-type components requiring dual-end machining.

To learn more, consult, or purchase a dual spindle CNC lathe, DONGS CNC is your ideal choice. DONGS CNC Machine Tools offers comprehensive professional services from pre-sales consultation to after-sales support, empowering customers to achieve success.