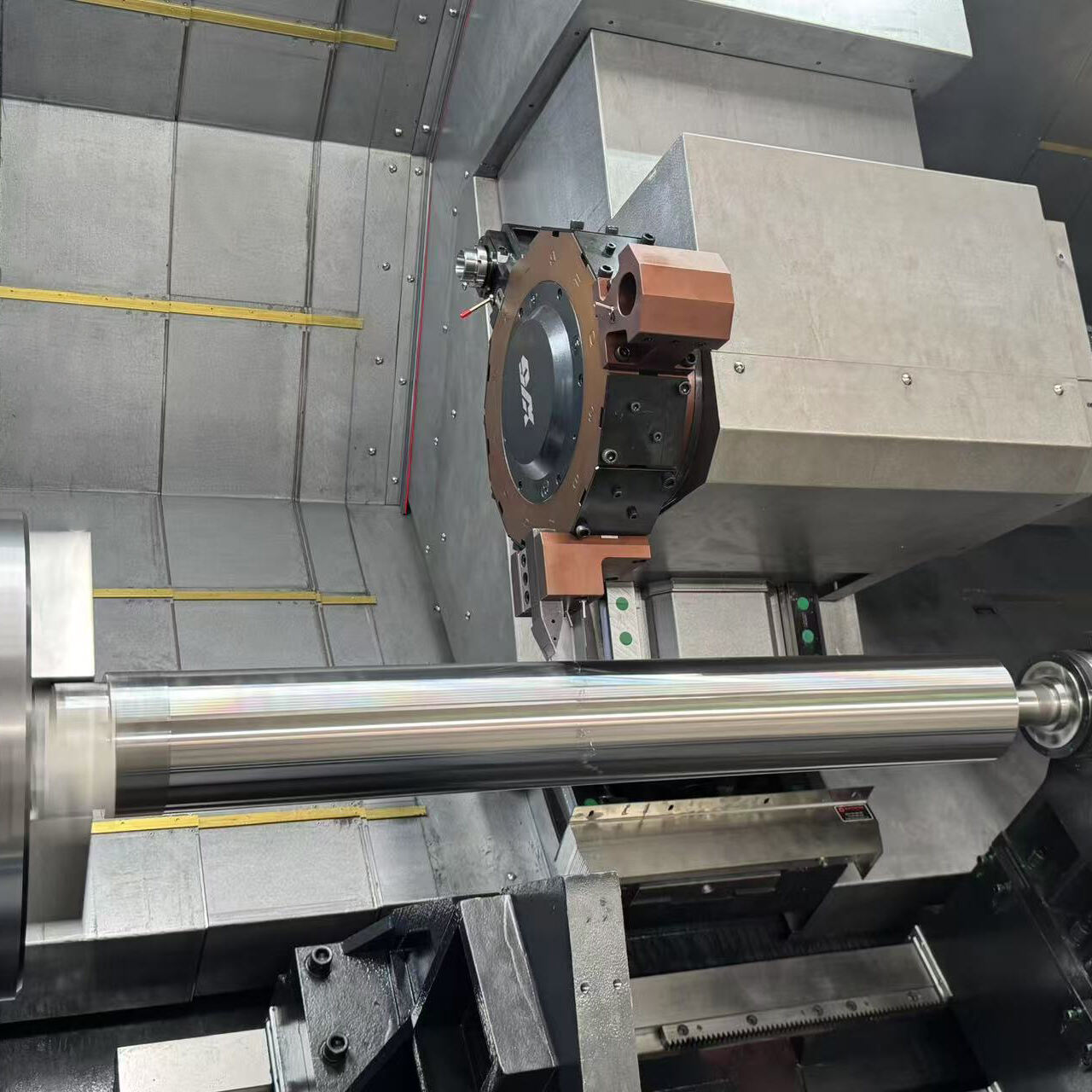

Y axis on lathe-A High-Efficiency, High-Quality Composite Machining Tool

The CNC Lathe with Y Axis breaks down the boundaries between turning and milling, and is often referred to as a turning-milling compound machining center. The Y-axis is a linear axis perpendicular to the X and Z axes, allowing the tool to move in an "up and down" direction. This enables the tool center to deviate from the workpiece's spindle rotation centerline. Combined with the precise circumferential indexing and rotational control of the spindle (C-axis), the machine tool gains the capability for off-center machining at any position around the circumference.

With a single workpiece setup, it can complete all turning, milling, drilling, tapping, eccentric machining, and even complex surface machining. This eliminates the datum conversion errors associated with multiple setups, significantly improving the overall accuracy of the part, particularly the positional accuracy between features. It saves the time required for transporting workpieces between different machines, re-indicating, and setup, greatly enhancing production efficiency.

Applications of Y axis on lathe:

Aerospace, Medical Devices, Automotive Industry, High-Precision Instruments

The CNC lathe with a Y-axis pursues ultimate efficiency, precision, and flexibility through highly concentrated processes. For modern manufacturers dedicated to processing complex parts, shortening delivery cycles, and enhancing core competitiveness, investing in Y-axis turning-milling compound technology is no longer an option, but a strategic decision crucial for future development. It integrates traditional "turning" and "milling," truly achieving a synergistic effect where "1+1 > 2".