What Are the Advantages of Dual-Turret CNC Lathes?

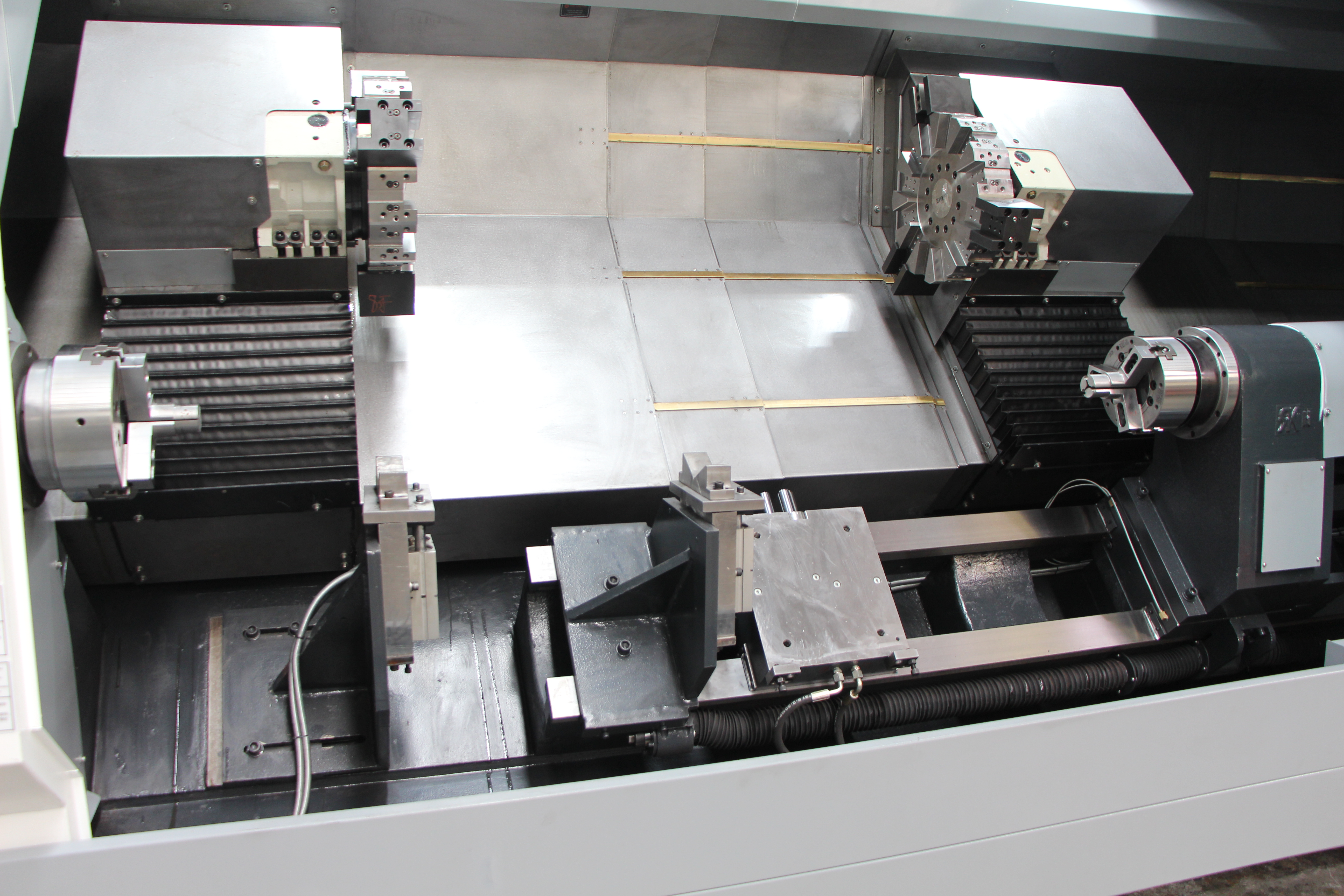

The most distinctive feature of a dual-turret CNC lathe is its two independently controlled turrets. In today’s pursuit of efficient and precision manufacturing, twin turret cnc lathes, with their unique technical advantages, have become an ideal solution for batch processing of complex parts.

Through the coordinated operation of the dual turrets, the machine enables truly parallel machining. While the front turret performs facing operations, the rear turret can simultaneously complete outer diameter finishing; when one turret carries out rough machining, the other can proceed with finishing. This machining model can shorten the cycle time by approximately 30–50%, making it particularly suitable for high-volume production scenarios.

For shaft or sleeve-type parts requiring machining on both ends, traditional processes necessitate secondary clamping. The dual-turret configuration supports completing all operations in a single setup, not only saving repositioning time but also eliminating datum conversion errors, ensuring precise positional relationships between features on both ends.

Dual-turret CNC lathes have successfully addressed the efficiency bottlenecks and precision challenges of traditional machining through technological innovation. For manufacturing enterprises committed to enhancing core competitiveness and achieving industrial upgrading, the rational application of dual-turret technology will become a key measure to break through production capacity limitations and ensure quality stability. In the wave of intelligent manufacturing, this technology will continue to play a vital role, helping enterprises gain a competitive edge in the market.