22 Jan 2026

22 Jan 2026

Discover how CNC turning centers drive precision manufacturing in aerospace, automotive, medical, and energy sectors. Boost efficiency, accuracy & ROI—explore real-world uses now.

Can your CNC turning center handle diverse workpieces? Discover how programmable operations, live tooling, and versatile tooling boost flexibility, productivity, and innovation. Learn more.

How to test CNC turning center performance? Discover proven methods, KPIs like cycle time & accuracy, and predictive maintenance tips. Download the full guide now.

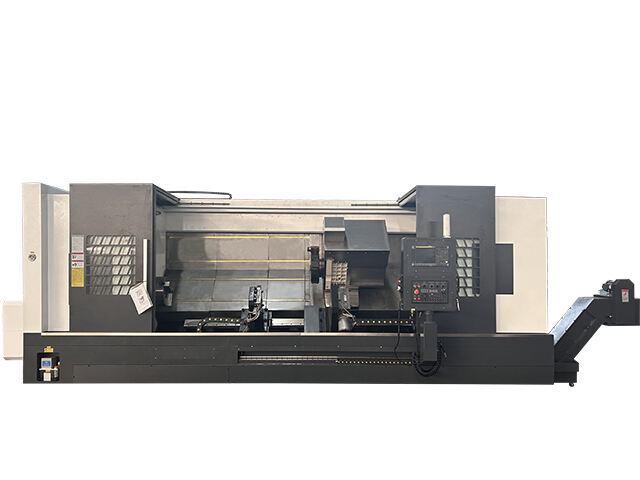

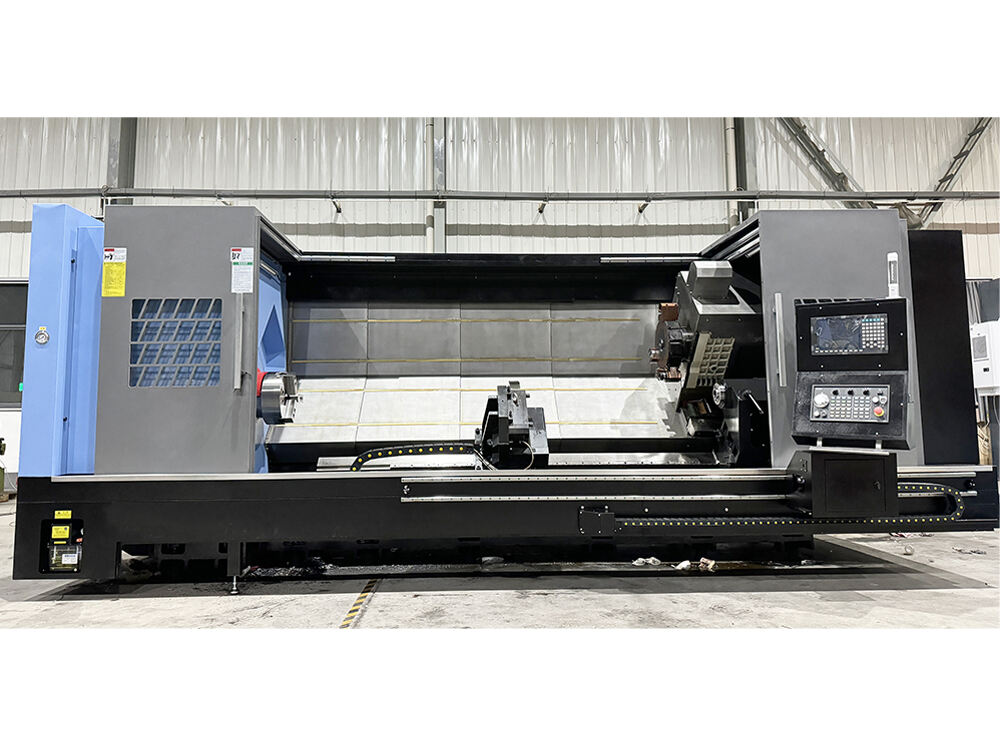

When choosing a CNC lathe, there are several factors to consider to ensure that the lathe you choose is suitable for the job. Processing needs: Determine the type of material to be used as well as the size and processing accuracy, which can help dete...

1. Before starting the CNC lathe, you must carefully check whether the lubricating oil of the lathe is sufficient so that the machine can be lubricated normally. 2. Carry out a comprehensive inspection of the lathe, including the lubrication system a...

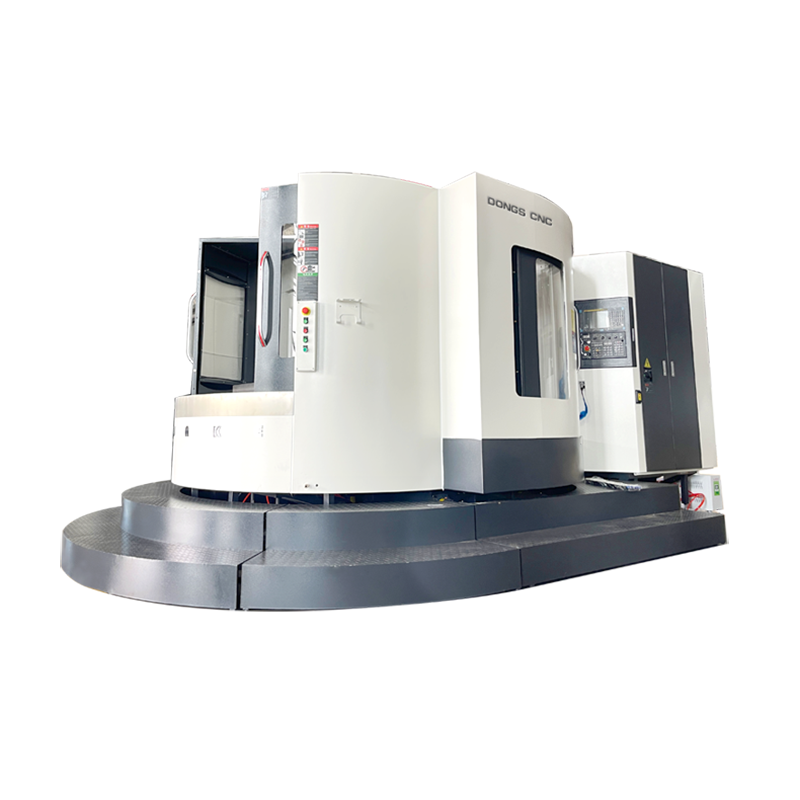

Vertical machining centers have several significant advantages, including machining stability and cutting force transmission, making them ideal for efficient, high-precision machining. The vertical layout of the vertical machining center makes workpi...

Medium and large turning centers (also called CNC turning centers) have many advantages in modern manufacturing and are ideal for a variety of industrial applications. Here are the main advantages of medium and large turning centers: These machines a...

In today's highly competitive manufacturing industry, efficiency and precision are particularly important. Slant bed linear CNC lathes have become a game changer in the current manufacturing industry. They can help companies process precision and exq...

The use of remote technology in CNC lathes can significantly improve production efficiency by streamlining processes and minimizing downtime This innovation allows for real-time monitoring

To ensure optimal performance and extend the lifespan of fully automatic CNC lathes regular daily maintenance is crucial Follow essential steps like cleaning lubrication and inspection to keep the machine in top working condition

To ensure optimal performance and extend the lifespan of fully automatic CNC lathes regular daily maintenance is crucial Follow essential steps like cleaning lubrication and inspection to keep the machine in top working condition

Explore the versatility and growing demand of slant bed CNC lathes in various industries including automotive, aerospace, and medical sectors. Learn about their benefits, key features, and future trends enhancing precision and sustainability. Discover how DONGS SOLUTION and Dongs Cnc Lathe are spearheading advancements in CNC technology.

Explore the stability and accuracy of flat bed CNC lathes, crucial for quality machining in industries. Discover their performances enhanced by CNC technology, and learn about the advantages between flat bed and slant bed CNC lathes from Dongs Cnc Lathe and DONGS SOLUTION.

Explore the advancements and applications of Horizontal Machining Centers (HMCs) in modern industries, emphasizing precision, efficiency, and cost-effectiveness. Discover their pivotal role in aerospace and automotive sectors with DONGS SOLUTION and Dongs Cnc Lathe.

Explore Dongshi CNC's visionary approach towards innovative mechanical processing technologies, focusing on advancements in CNC lathe technology and automation. Discover how these innovations are shaping the future of manufacturing.