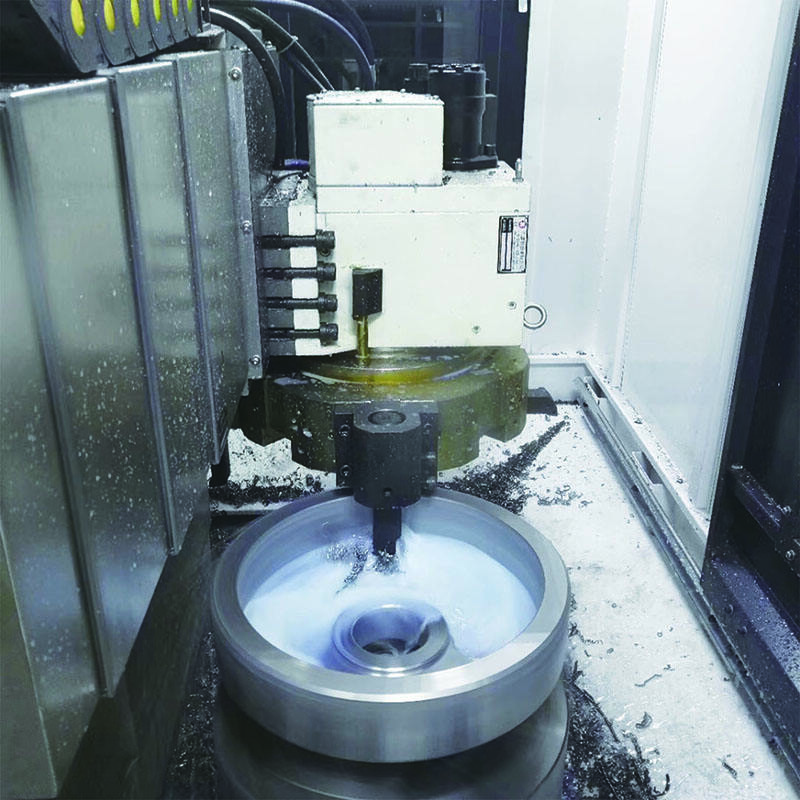

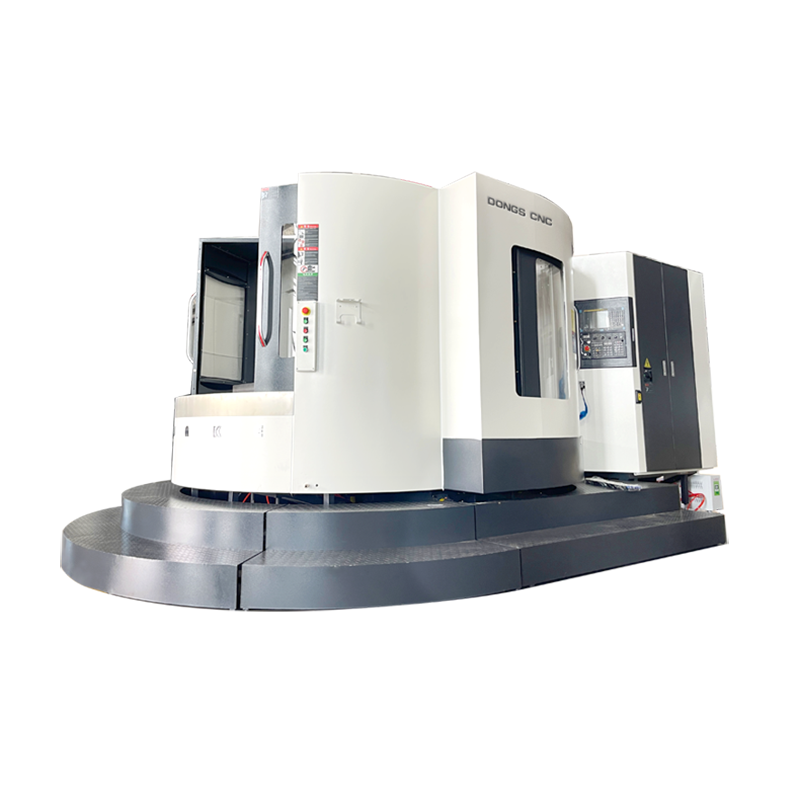

VTC 650CNC vertical lathe

- The vertical guide rail of the machine tool adopts a cross-slider structure, and the castings such as the column, base and slide are all made of gray cast iron. The column and slide rails are all high-frequency quenched, and the moving surface of the guide rail is plastic-coated to ensure the stability and precision retention of the machine tool for long-term use. The machine tool is fully enclosed for protection and has a beautiful appearance.

- The spindle transmission of the machine tool adopts a spindle servo motor and imported spindle bearings. It has low speed and high torque, which is suitable for strong cutting; suitable for semi-finishing and finishing of parts.

- The X/Z axis feed is automatically controlled by the same servo motor. The Z axis adopts a balanced weight, with reliable structure and low failure rate.

- The X/Z axis of the machine tool adopts precision ball screws and is equipped with imported screw-specific bearings to meet the requirements of high-precision and high-rigidity cutting.

- The spindle of the machine tool adopts thin oil lubrication, the lubricating oil is circulated externally, and the spindle bearings have good fan heat effect; or the spindle unit structure. The machine tool guide rails are lubricated by an electric oil pump.

- The machine tool is equipped with a hydraulic chuck with high positioning accuracy and large clamping force.

Introduction

| Specifications | Unit | VTC500 | VTC650 | VTC750 |

| Maximum rotation diameter of workpiece | mm | 500 | 650 | 750 |

| block type | mm | 400 | 550 | 650 |

| Hydraulic chuck | inch | 12" | 15" | 21" |

| Spindle speed | rpm | 50-1250 | 50-1250 | 50-1000 |

| Spindle model | - | A2-8 | A2-8 | A2-11 |

| feed rate | mm/min | 0.1-5000 | 0.1-5000 | 0.1-5000 |

| Vertical movement distance of tool carrier | mm | 500 | 550 | 700 |

| Horizontal moving distance of tool rest | mm | -50-275 | -50-325 | -50-375 |

| Linear guide rail | mm | 45pin roller | 45pin roller | 55pin roller |

| X/Z-axis fast moving speed | m/min | 15/12 | 15/12 | 15/12 |

| Turret form | - | Horizontal station 12 | Horizontal type 8 station | Horizontal station 8/vertical station 4 |

| Main motor power | kw | 11/15 | 15/18.5 | 22/30-286 |

| X/Z Power聽 of feed motor | kw | 1.6/2.4 | 2.4/2.4 | 2.4/2.8 |

| X/Z lead screw diameter | mm | Φ40 | Φ40 | Φ40/50 |

| Repeated positioning accuracy of machine tool | mm | ±0.005 | ±0.005 | ±0.005 |

| Outline dimension of machine tool | m | 1.8×1.8×2.5 | 1.95×1.85×2.65 | 2.3×2×2.3 |

| Overall weight (about) | t | 4.2 | 5.2 | 7.2 |