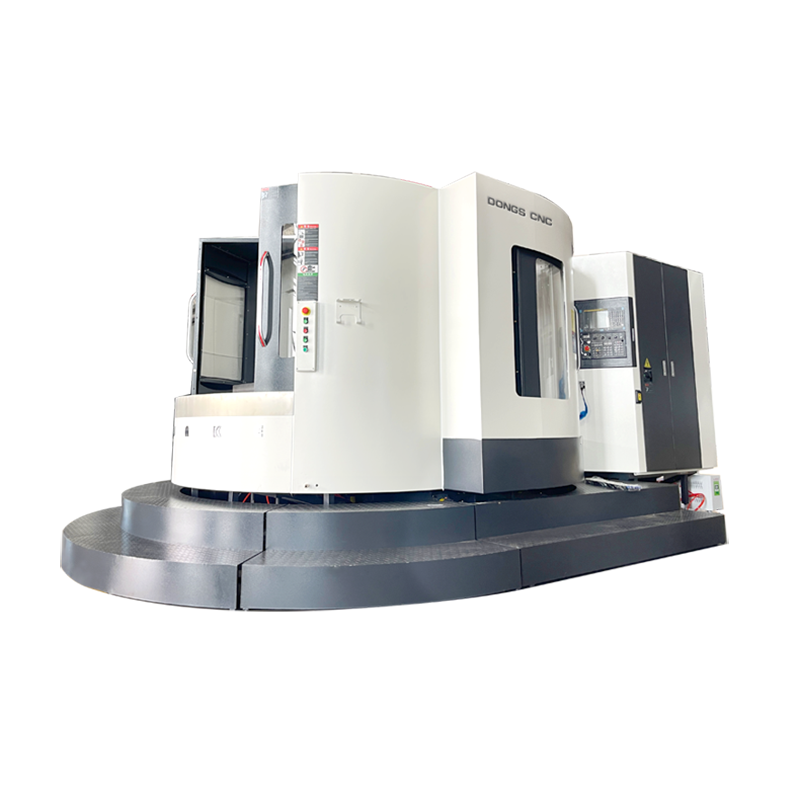

| Specifications |

Unit |

VMC650 |

VMC640 |

VMC550 |

| Table size |

mm |

900×410 |

1000x360 |

800×260 |

| Table maximum load |

kg |

400 |

300 |

200 |

| X/Y/Z axis travel |

mm |

650x450x500 |

650x400x500 |

550x320x450 |

| Distance between spindle centerand column guide surface |

mm |

500 |

440 |

350 |

| Distance between spindle end face and worktable surface |

mm |

100-600 |

100-600 |

80-530 |

| X/Y/Z Max. Rapid traverse |

m/min |

24/24/24 |

24/24/24 |

24/24/24 |

| Maximum spindle speed |

r/min |

8000 |

8000 |

8000 |

| Spindle taper hole |

- |

BT40/120 |

BT40/120 |

BT40/120 |

| Spindle motor |

kw |

5.5-7.5 |

5.5-7.5 |

3.7-7.5 |

| X / Z torque motor |

n.m |

10/10/15 |

7/7/15 |

6/6/15 |

| Screw diameter |

mm |

Φ32/12 |

Φ32/12 |

Φ28/12 |

| Repeat positioning accuracy |

mm |

±0.004 |

±0.004 |

±0.004 |

| Guide rail form |

mm |

Track |

Track |

Track |

| Magazine capacity |

t |

16/16 |

16/12 |

12 |

| Tool magazine form |

- |

Robot/Bonnet |

Robot/Bonnet |

Robot/Bonnet |

| Machine size (L x W x H) |

m |

2.5×2.2×2.5 |

2.5×2.2×2.5 |

2.2×2×2.3 |

| Machine weight (approx.) |

t |

4 |

3.5 |

3 |