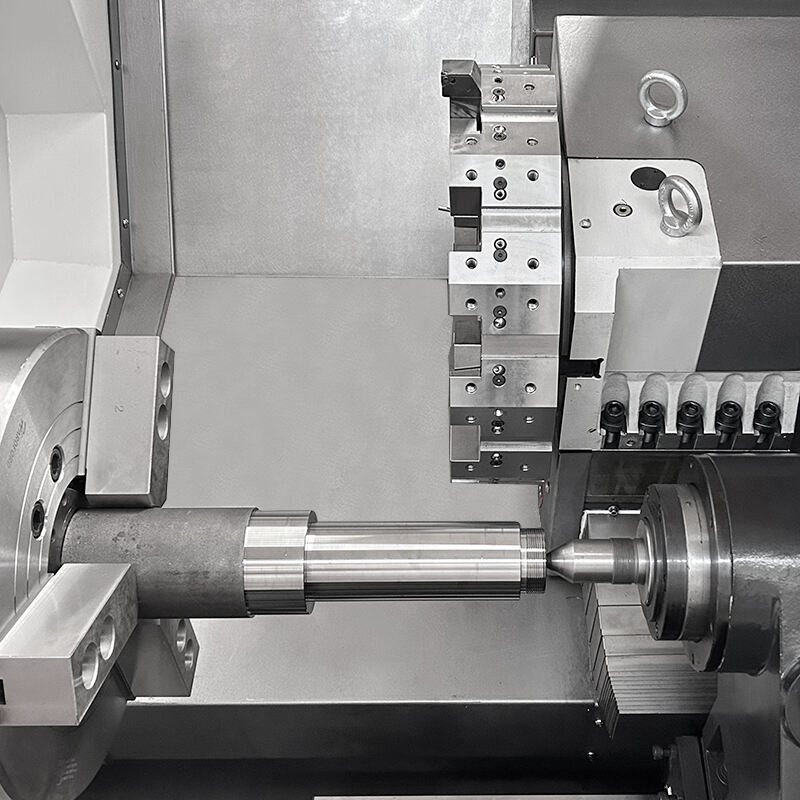

Slant bed CNC lathe

- High precision Roller linear guide

- High precision ball screw

- lmported precision bearing

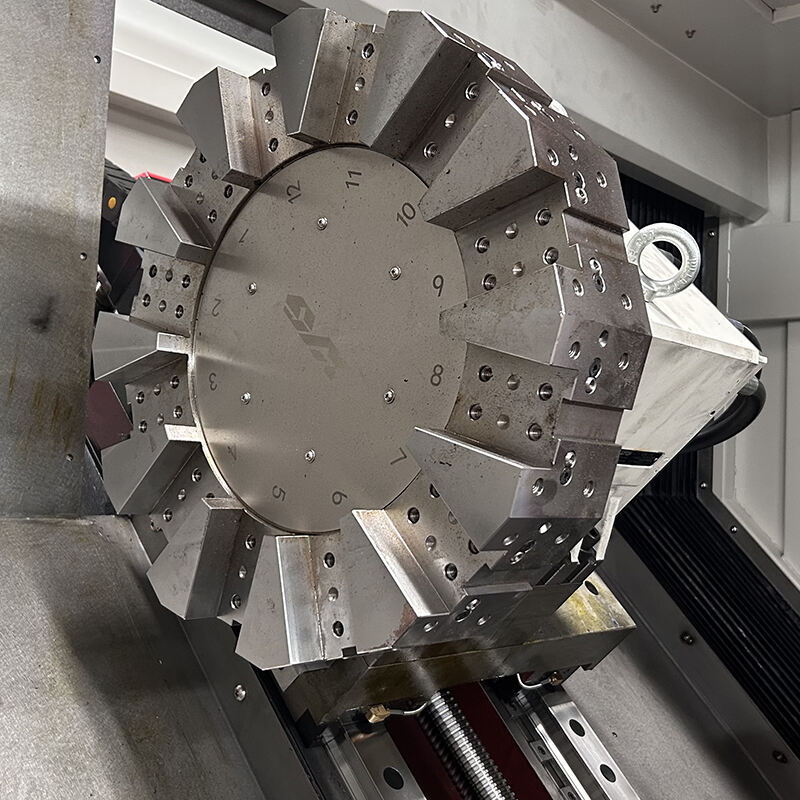

- Servo hydraulic turret

- Opsyonal na 12 Station live tooling

- Tool setting instrument ay opsyonal

- Main shaft synchronous belt drive

Panimula

Unang pangunahing estruktural na characteristics ng machine tools:

1, Ang 45° slanted bed ay naisda sa isang piraso at gawa ito ng high-strength cast iron. Ang mga reinforcing ribs ay optimally arranged gamit ang finite element analysis, high-strength cast iron materials, resin sand molding, at sapat na secondary aging at natural aging upang gawing mataas ang rigidity ng mga pangunahing bahagi ng machine tool at siguraduhing matatag ang machine tool para sa long-term use.

2、 Parehong X at Z axes ay gumagamit ng high-precision, high-load capacity, at high-reliability linear rolling guides. Gumagamit ang Z axis ng 6-slider design upang malaking dagdagan ang rigidity, at may automatic forced lubrication, ito ay nagbabawas sa friction resistance ng feed motion at nagpapabuti sa accuracy at life ng machine tool; mas mataas ang feed speed at positioning accuracy ng machine tool.

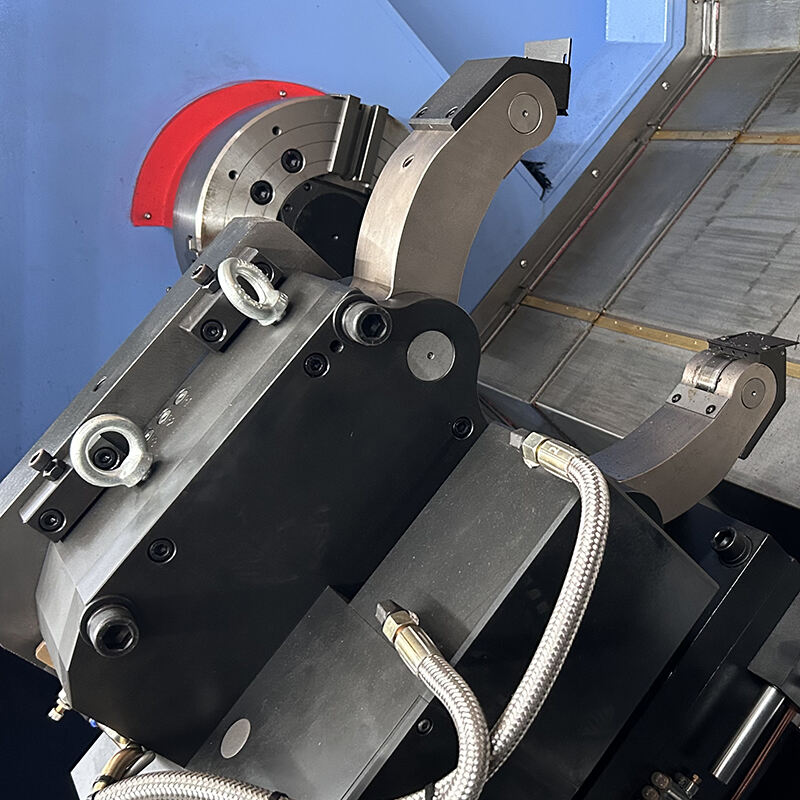

3、 Ang bahagi ng tailstock ay may programmable control, ang sleeve ay isang panloob na istraktura ng pag-ikot, at ang paggamit ng isang pin ay maaaring malaking mapabuti ang katatagan at katiyakan ng pag-cut. Ang katawan ng tailstock ay nilulock ng awtomatikong hydraulic lock, at ang kabuuang paggalaw ay standard na may awtomatikong hydraulic, at opsyonal ang drive ng servo motor.

4, Ginagamit ng spindle ang kombinasyon ng malalaking diametrong presisyon angular contact thrust ball bearings at double-row cylindrical roller bearings. Dinrive ng high-power at high-torque servo motor ang spindle, na may mahusay na katigasan at mataas na torque sa mababang bilis.

| Kakayahan | yunit | TCK700 | |||

| Distansya sa pagitan ng mga sentro | mm | 1100 | 1600 | 2100 | 3100 |

| Chuck size | tinta | 12 | |||

| Max. mag-swing sa ibabaw ng kama | mm | 780 | |||

| Max. mag-swing sa ibabaw ng cross slide | mm | 500 | |||

| Ang lapad ng linear na gabay na riles | mm | 55/55 | |||

| PAGPASAYAK | |||||

| X-Axis Rapid Traverse (Mabilis na Paglalakbay sa Axis ng X) | M/min | 16 | |||

| Z-Axis Rapid Traverse (Ang Mabilis na Paglalakbay sa Z-Axis) | M/min | 16 | |||

| Paglalakbay ng X axis | mm | 370 | |||

| Z axis na paglalakbay | mm | 1100 | 1600 | 2100 | 3100 |

| PANGUNING SINILAN | |||||

| Max. spindle speed | rpm | 2000 | |||

| Max. Pwersa ng Spindle | KW | 30 | |||

| Spindle nose | - | A2-11 | |||

| Kapasidad ng bar | mm | 91 | |||

| TURRET | |||||

| Numero ng tool station | - | 12 | |||

| Uri ng torret | - | 12-istasyon na hydraulic servo turret | |||

| TAILSTOCK | |||||

| diameter ng bulate | mm | 150 | |||

| paglalakbay sa bulate | mm | 200 | |||

| paglalakbay ng tailstock | mm | 900 | 1400 | 1900 | 2900 |

| Tailstock taper | - | MT5 | |||

| Sukat | |||||

| Sukat ng packing | m | 5.3 | 5.8 | 6.3 | 7.3 |

| Lapad | m | 2.25 | 2.25 | 2.25 | 2.25 |

| Taas | m | 2.55 | 2.55 | 2.55 | 2.55 |

| Net Weight | Kg | 7200 | 8700 | 9800 | 12500 |

FAQ

Q:Sino kami?

A: Kami ay isang tagapagtatag ng pag-unlad sa larangan ng kagamitan na CNC. Kami ay isang manunuo na tumutok sa paggawa ng mga turning center na mataas ang produktibidad, CNC slant-bed lathes, CNC flat lathes, machining centers, at vertical lathes na katamtaman at malalaki. Seryosamente inuulit namin ang pagsangguni sa mga estratetikong partner sa buong mundo upang ipag-uusad ang mga trend sa industriya.

Q: Paano ko mapipili ang pinakamahusay na makina?

A: Pakisabi sa amin ang iyong mga espesipikasyon at maaari naming pumili ng pinakamainam na modelo para sa iyo, o pumili ka ng eksaktong modelo.

Q: May aktwal na fabrica ba kayo?

A: Oo, kami ay isang manununo ng CNC lathe sa Lungsod ng Tengzhou, Lalawigan ng Shandong. Mayroon kaming isang propesyonal na pangkat ng teknikal, pang-venta, at pagkatapos-mga serbisyo.

Q: Anong mga serbisyo ang maaaring aming ibigay?

A: Tinatanggap na termino ng paghahatid: FOB, CFR, CIF, EXW; Tinatanggap na mga salapi para sa pagbabayad: USD, RMB; Tinatanggap na uri ng pagbabayad: T/T, L/C, Western Union; Ginagamit na mga wika: Ingles, Tsino

Q: Paano namin siguraduhin ang kalidad?

A: Gaganapin ang mga sample bago ang pagsasabuhay ng masang produksyon; isasagawa ang huling inspeksyon bago ang pagpapadala;

Q: Bakit dapat bumili sa amin habang may iba pang mga tagatulong?

A: Specialize kami sa paggawa ng mga produkto na ito sa loob ng 20 taon at nakamit na ang sertipikasyong ISO 9001, sertipikasyong CE at sertipikasyong EAC.

Q: Pwede ba mong ipersonal ang makina?

A: Oo, nag-integrate kami ng disenyo at pag-unlad, may karanasang mga inhinyero at tekniko sa paghahanda.

Q: Pwede ba akong bisitahin ang inyong fabrica?

A: Sige, sobrang tinanggap ka namin.