cNC გარდაქმნა

- Მაशინური ინსტრუმენტების წარმოებლები

- Ზუსტი მაशინური ინსტრუმენტების წარმოებლები

- Მაღალი სიზუსტის ბურთის ხრახნი

- Მაღალი სიზუსტის როლიკების ლინეარული სახელური

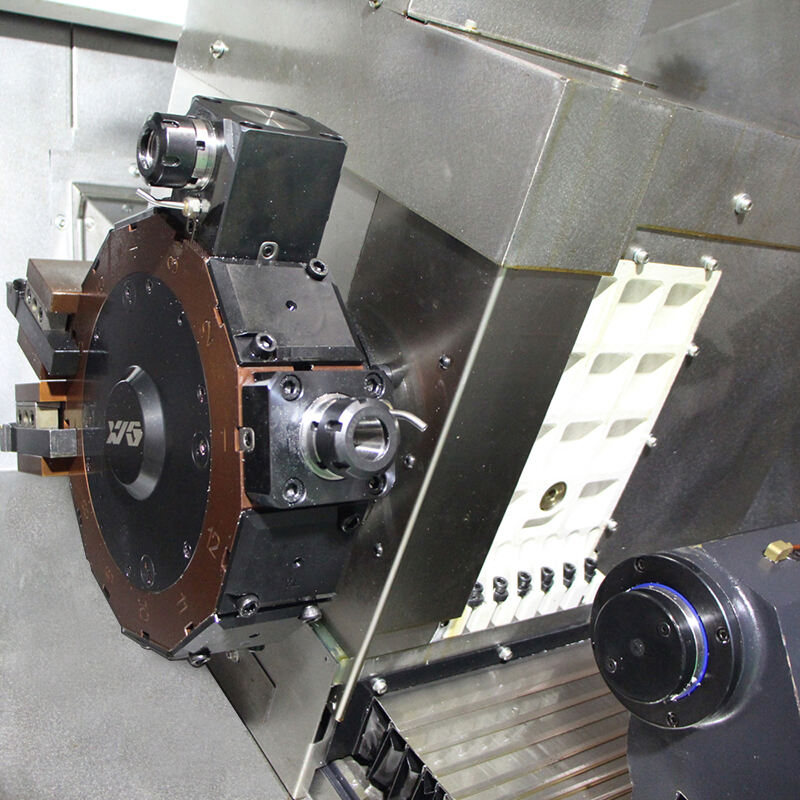

- 12-ადგილიანი ელექტრო ტურრეტი

- Მაგნიტური რგოლის ენკოდერი

- Ჰიდრავლიკური პროგრამირების უკანა საყრდენი

- A2-6/A2-8 მძიმე დანიშნულების შპინდი

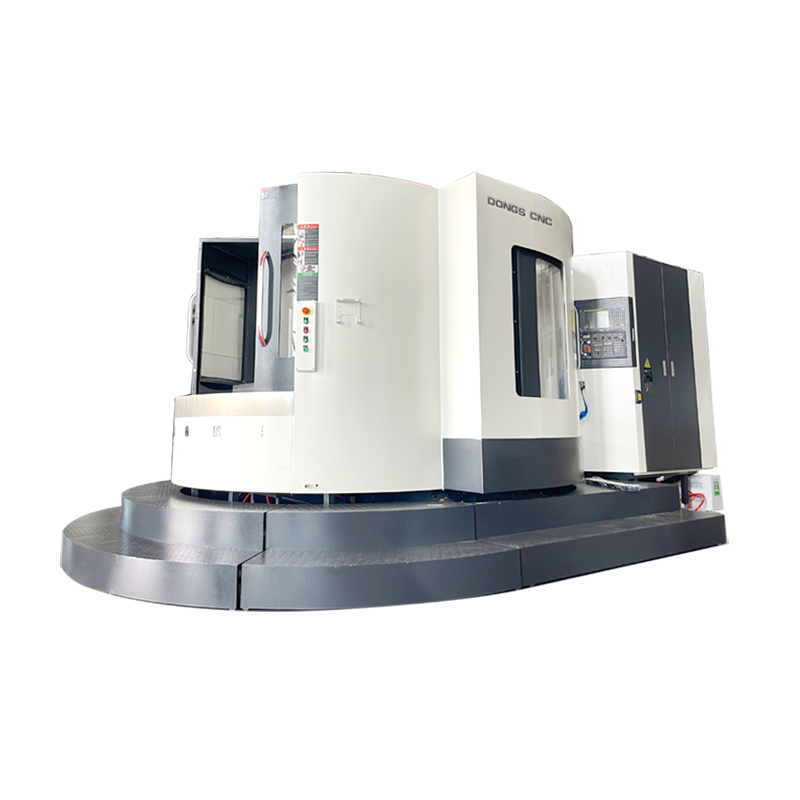

Შესავალი

CNC როტაციის ძირითადი მახასიათებლები

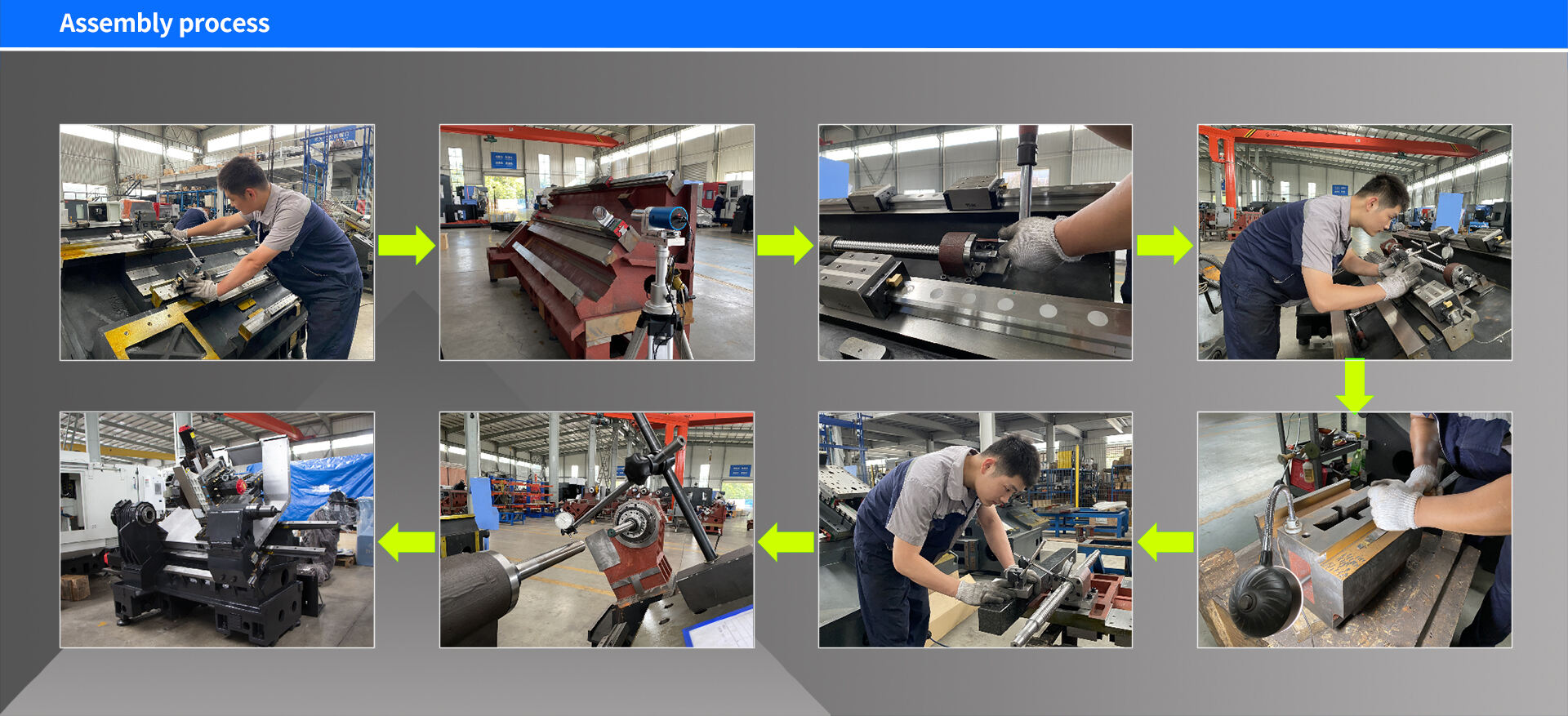

1. საწყვეტი

Ეს მანქანა გამოიყენება ინტეგრირებულ დიაგონალური საწყვეტის სტრუქტურას, რომელიც 30 გრადუსიან კუთხით ჩანართულია. ის შემორჩენილია HT300 მაღალი ძალიანობის ქვაბის მასალისგან რეზინ 白沙 მოდელირების პროცესით. გარკვეული ქსელის ფორმის განკუთვნილი განსაზღვრული რიბების განლაგებით და გერმანიიდან შემოსული მაღალი ზუსტობის როლის სისტემით, მიღებულია დაბალი წინააღმდეგობისა და მაღალი ძალიანობის მუშაობის მახასიათებლები. ეს სტრუქტურა მilikiს მაღალი ვიბრაციის და გარდაქმნის წინააღმდეგობას, რაც ეფექტურად უზრუნველყოფს მუშაობის ზუსტობის სტაბილობას და მხარდაჭერს მაღალი სიჩქარის გადაადგილების ფუნქციას, რაც საკმარისად ამéliერებს მუშაობის ეფექტიურობას.

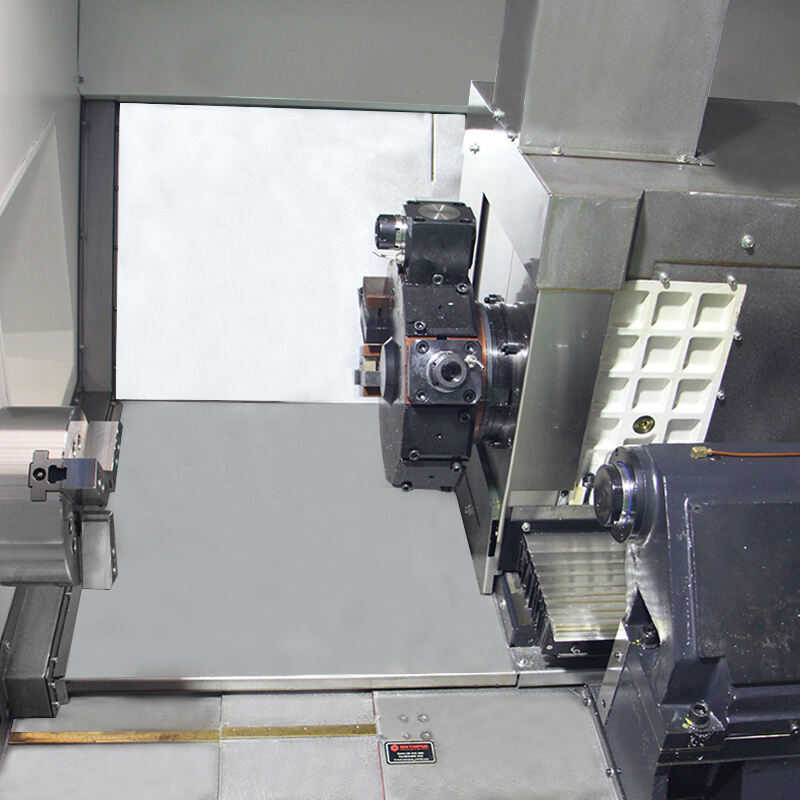

2. ორ ღერძის მომწიდვა

Z ღერძის მოძრაობის მექანიზმი შესრულდება სადელის კომპლექსის გამოყენებით ბედის რეილზე, ხოლო X ღერძის მოძრაობა ხდება სლაიდის კომპლექსის გამოყენებით, რომელიც გადააქვს ინსტრუმენტულ სისტემას. Дვი-ღერძიანი ძალის გადაცემა ხდება იაპონურ THK სწრაფი ბურტის წყვილით, რომელიც ელასტიურ კუ夫ით პირდაპირ დაერთება Yaskawa სერვო-მოტორს. ეს გადაცემის სქემა მისამართების სიზუსტე აქვს მიკრონურ დონეზე, ეფექტუალურად გამოიწვევს შებრუნების შუალედებს და უზრუნველყოფს, რომ ტრაექტორიის განახლების შესაბამისობა მიიღოს ±0.003 მილიმეტრის სტანდარტი.

3. სადელი და სლაიდი

Სადრომის კომპონენტები ვიზუალიზებულია ინტეგრალური ლითოგრაფიის პროცესის მეშვეობით, ხოლო მასალა არის HT300 ქვაბი, რომელიც ერთმანეთს უთანასწორობას უზრუნველყოფს სიცილის მიმართ. სლაიდ ერთეული აღარის შვიც Gaussian Schneider-ის როლის სისტემით. X ღერძის გადამოწმება ინტეგრირებულია მაღალ ზუსტობის წინადადებული სკრუს მექანიზმით. ძალის გადაცემის ბმული იყენებს ნულოვან წინადადების კოუპლინგ მოწყობილობას, რომელიც შე祺ვებულია სრულად დახურული წიკლის გამოხატვით საშუალებას, რომლის მეშვეობითაც ზუსტად კონტროლირებულია ინსტრუმენტის გზა. სპეციალურად დამუშავებული ჭადრის გამოსავალი მექანიზმი შეძლებს კომპენსაციას მექანიკურ ჰუნდების გამო, რომლებიც გამოწვევის გამო მოხდება გრძელი გამოყენების შემდეგ, და მას შეიძლება დაცვას მოწყობილობის გრძელი ზუსტობა.

CNC ჩრობის ძირითადი სფეროები :

Ავტომობილის ნაწილების წარმოება: შესაბამისია ავტომობილის ნაწილების მაღალ ზუსტობის წარმოებისთვის, როგორიცაა ღერძები, ჰუბები, გარში, მანქანის ბლოკები და ა.შ.

Ჰაერონავტიკური ინდუსტრია: იდეალურია კრიტიკული ჰაერონავტიკური ნაწილების წარმოებისთვის, რომლებიც მოითხოვენ მაღალ ზუსტობას და მაღალ ხარისხის ზედაპიროვან დასრულებას.

Გრძელი მაशინების შემუშავება: დახორციელებულია დიდი კომპონენტების შემუშავებისთვის, რომლებიც გამოიყენება საშინელო მასალებში და ინდუსტრიულ მაशინებში.

Ღამე-და საქაღალდე ინდუსტრია: გამოიყენება ღამე-და საქაღალდე ინდუსტრიისთვის ფართოდ გავრცელებული ნაწილების, როგორც ვალვები, მისამართლები და ჩასართვის მაशინების შემუშავებისთვის.

Ზოგადი მეტალურგიული მუშაობა: განსაზღვრულია ზოგადი შემუშავებისთვის, როგორიცაა მაशინური ნაწილების, იнструმენტებისა და სხვა ზუსტი კომპონენტების შემუშავება.

Ინსტრუმენტებისა და ფორმების შემუშავება: იდეალურია მოლექულებისა და ფორმების შემუშავებისთვის მოლექულური ნაწილების შემუშავებისთვის.

Ენერგეტიკის სექტორი: განსაკუთრებით მნიშვნელოვანია ნაწილების შემუშავებისთვის, რომლებიც გამოიყენება ელექტროენერგიის წარმოებაში და განახლებადი ენერგიის მაशინებში.

| Ტექნიკური მახასიათებლები | ერთეული | TCK52DY | |

| Დამუშავების დიაპაზონი | Მაქსიმალური გარდატანის დიამეტრი საწვავზე | მმ | φ650 |

| Მაქსიმალური გარდატანის დიამეტრი საკოლოზე | მმ | φ400 | |

| Დამუშავების მაქსიმალური დიამეტრი | მმ | φ470 | |

| Ცენტრის მანძილი | მმ | 600/800/1000 | |

| Ღერძი | Spindle Head ტიპი | მმ | A2-6 |

| Შპინდი ხვრელის დიამეტრში | მმ | 66/79 | |

| Ბარის დიამეტრი < | მმ | 50/65 | |

| Მაქსიმალური სპინდლის სიჩქარე | r/min | 4200 | |

| Ძირითადი მოტორის შეფასების მოცულობა | Კვ | 11-15 | |

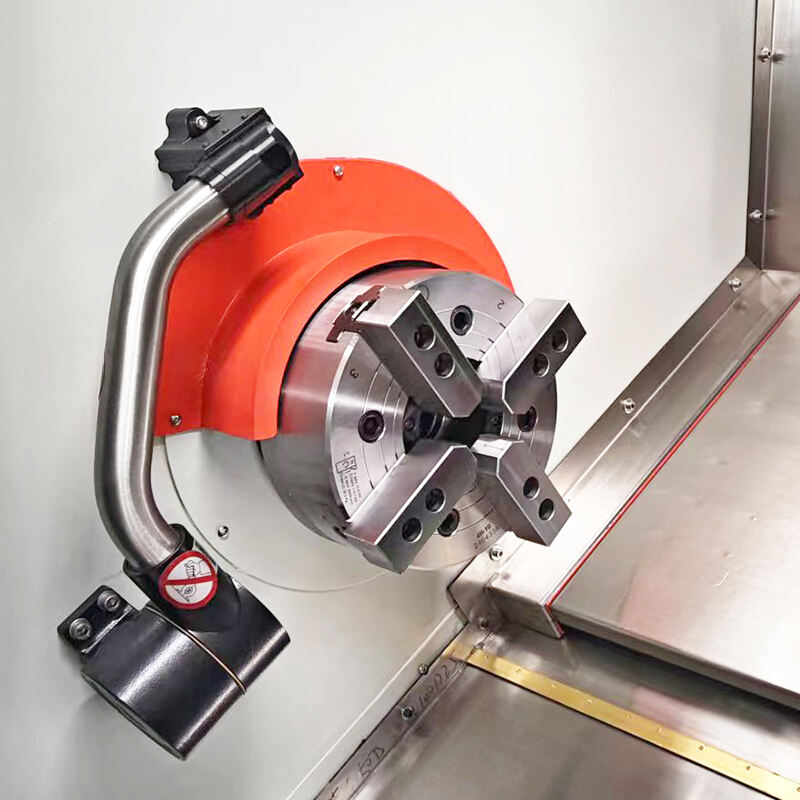

| Ფიქსატურა | Ჰიდრაულიკური ჩაკი | ინჩი | 8/10 |

| Კუდიანი | Კუდიანი მუყაოს ყურება | / | MT5 |

| Კუდიანი ხორცის გადაადგილების ფორმა | / | Სლაიდის გადაადგილება | |

| Ქუთის დიამეტრი | მმ | 80 | |

| Tailstock მოგზაურობა | მმ | 490/740/990 | |

| Კუდიანი ხმელეთის სახელმძღვანელო ფორმა | / | Მყარი რკინიგზა | |

| Სადელი | Დახრის კუთხე | Გრადუსი | 30 |

| Მოძრაობის მანძილი X | მმ | 260 | |

| Მოძრაობის მანძილი Z | მმ | 610/830/1070 | |

| Y ღერძის მაქსიმალური გადაადგილება | მმ | ±50 ყვარის რეილი | |

| Სწრაფი მოძრაობის სიჩქარე X/Z | m/Min | 24/24 | |

| Სერვო მოტორი X/Z/Y | Კვ | 2.5/2.5/1.4 | |

| ტურეტი | Ტურეტის დიამეტრი | მმ | Გაჭრის დიამეტრი 380 |

| Დრო ინსტრუმენტის შეცვლამდე | S | 0.5 | |

| Ინსტრუმენტის პოზიციების რაოდენობა | / | 12 სტაციონარი | |

| Ტურეტის ტიპი | Სერვო ჰიდროავტომატიკა | BMT55-12 სტაციონარი ძალი | |

| Ძალიან ღერ Gaussian ძალი | Კვ | 2.7 | |

| Ძალის ღერ Gaussian სიჩქარე | წთ/წთ | 4000 | |

| Სპრინგის ჩაკის მოდელი | / | ER32 | |

| Იнструმენტის ზომა | მმ | 25×25 | |

| Ცენტრის მანძილი | Ზომები | Წონა (შეადგილებით) | |

| 600 | 3350X2000X2300mm | 4000 კგ | |

| 800 | 3600X2000X2300mm | 4300kg | |

| 1000 | 3600X2000X2300mm | 4700 კგ | |

Ხელიკრული

Q: ვინ ვართ?

A: ჩვენ ვართ ინოვაციების მიმღები ლიდერი CNC მოწყობილობების სფეროში. ჩვენ ვართ წარმოებელი კომპანია, რომელიც მოიგონება საშუალო და დიდი ზომის ეფექტური გადარტყავის ცენტრების, CNC დიაგონალური მახარის, CNC სიბრტყის მახარის, გამოსაработი ცენტრების და სამრავლო მახარის წარმოებაში. გულისხმობთ გლობალურ სტრატეგიულ პარტნიორებს, რომ ერთად განიხილოთ ინდუსტრიის ტენდენციები.

Q: როგორ მოიხერხებ ყველაზე გასარგებლი მაशინი?

A: გთხოვთ მიუთხროთ თქვენი სპეციფიკაციები და ჩვენ შეგვიძლია აირჩიოთ საუკეთესო მოდელი თქვენთვის, ან თქვენ აირჩიეთ ზუსტი მოდელი.

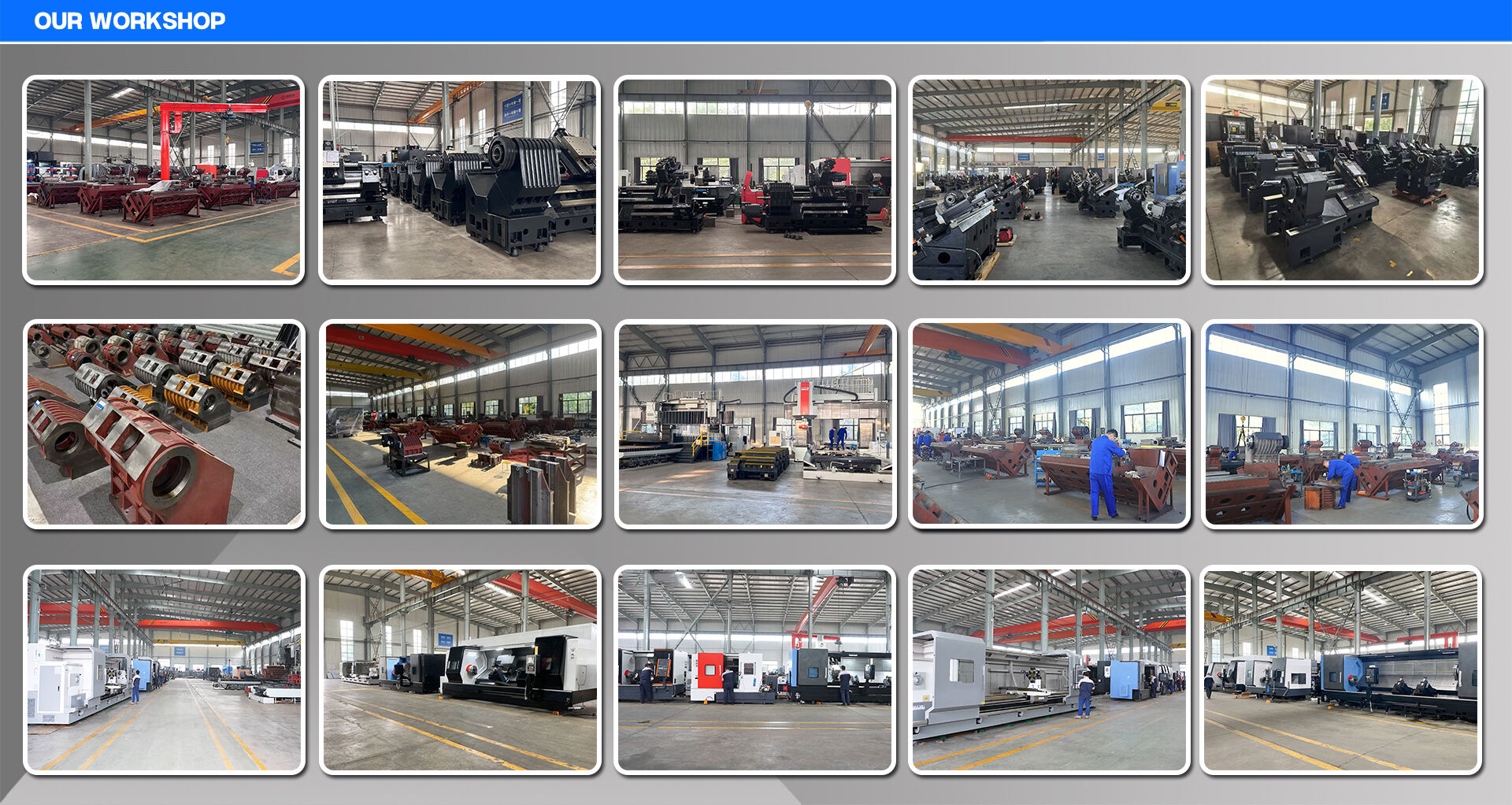

Q: გვაქვს ფიზიკური ფაბრიკა?

A: დიახ, ჩვენ ვართ CNC მახარის წარმოებელი Tengzhou City-ში, Shandong პროვინციაში. ჩვენ გვაქვს პროფესიონალური ტექნიკური გუნდი, გაყიდვის გუნდი და შემდეგ-გაყიდვის გუნდი.

Q: რომელ სერვისები შეგვიძლია გთავაზოთ?

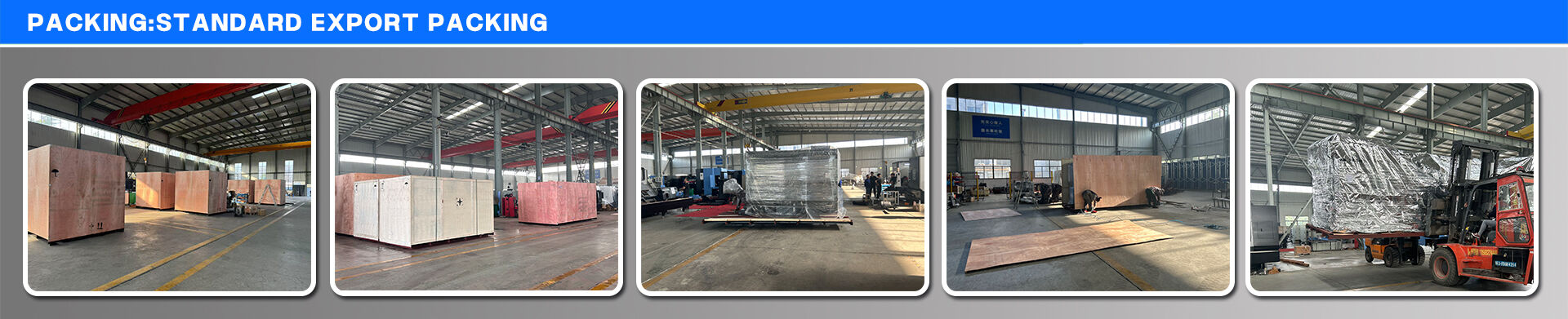

A: დანიშნული ტერმინები: FOB, CFR, CIF, EXW; მიღწევის ვალუტა: USD, RMB; მიღწევის ტიპები: T/T, L/C, Western Union; გამოყენებული ენები: ინგლისური, ჩინური

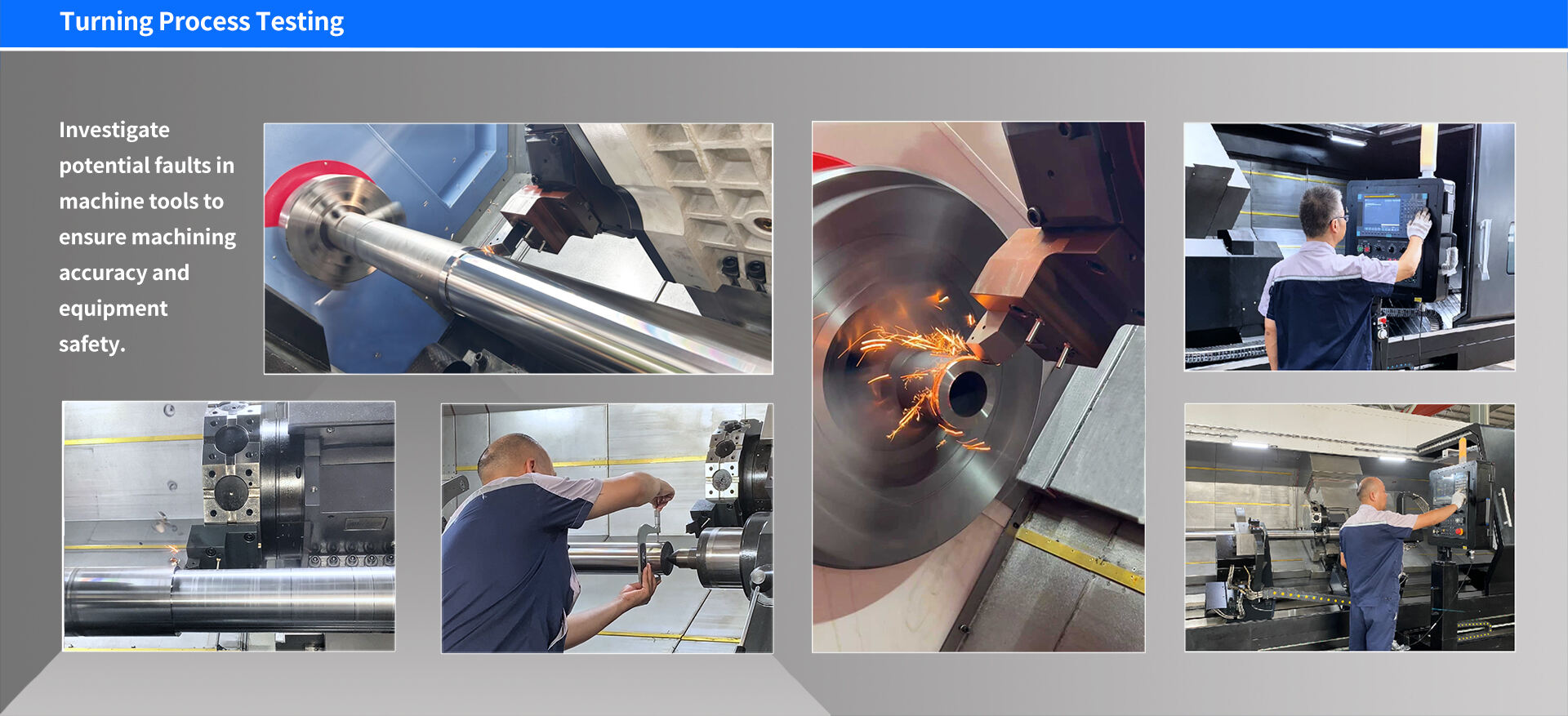

Q: როგორ დავარწმუნდით ხარისხის შესახებ?

A: მასალის წარმოებას წინააღმდეგ ყოველთვის განხილული ეკიმენტები არის; გაგზავნის წინ ყოველთვის განხილული არის საბოლოო შემოწმება;

Q: რატომ უნდა იყიდეთ ჩვენგან და არა სხვა მომწიფეებისგან?

A: ჩვენ 20 წლის განმავლობაში განსაკუთრებით ვქვემოვანდებით ეს პროდუქტები და მივიღეთ ISO 9001 სერტიფიკატი, CE სერტიფიკატი და EAC სერტიფიკატი.

Q: შეგიძლია მაशინის განსაკუთრებით შექმნა?

A: დიახ, ჩვენ ინტეგრირებული ვართ დიზაინში და განვითარებული, გამოცდილი ინჟინერებით და მონტაჟის ტექნიკებით.

Q: შემიძლია თქვენს ფაბრიკაში წავიდე?

A: კარგი, თქვენ ძალიან გაითავაზობთ.