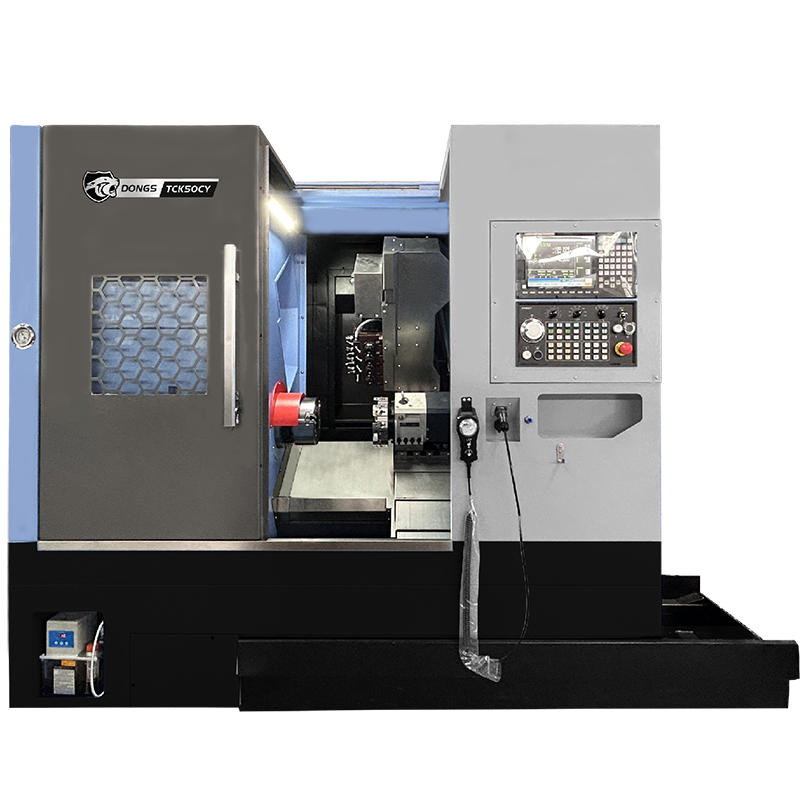

Heavy Duty CNC Lathe Vertical

- Machine tool manufacturers

- Precision machine tool manufacturers

- Taiwan High precision wire rail, lead screw

- Taiwan hydraulic chuck

- Taiwan brand spindle

- Taiwan brand turret

- Volumetric lubrication

- Matching hydraulic station

Introduction

Heavy Duty CNC Lathe Vertical Key Features:

The vertical guide rail of the machine tool adopts a cross-slider structure, and the castings such as the column, base and slide are all made of gray cast iron. The column and slide rails are all high-frequency quenched, and the moving surface of the guide rail is plastic-coated to ensure the stability and precision retention of the machine tool for long-term use. The machine tool is fully enclosed for protection and has a beautiful appearance.

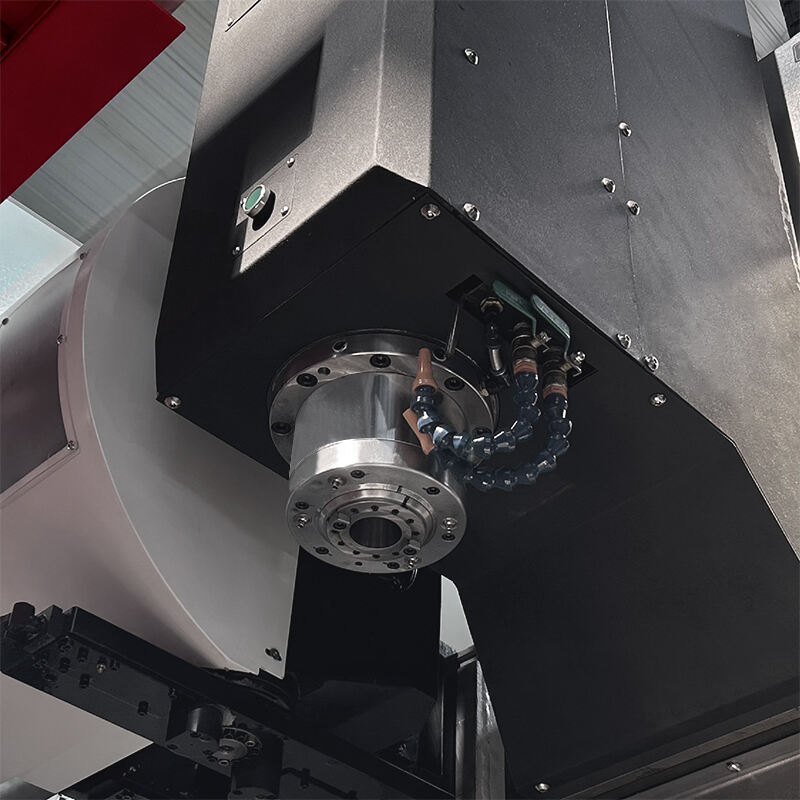

The spindle transmission of the machine tool adopts a spindle servo motor and imported spindle bearings. It has low speed and high torque, which is suitable for strong cutting; suitable for semi-finishing and finishing of parts.

The X/Z axis feed is automatically controlled by the servo motor. The Z axis adopts a balanced weight, with a reliable structure and a low failure rate.

The X/Z axis of the machine tool adopts a precision ball screw and is equipped with imported screw-specific bearings to meet the requirements of high-precision and high-rigidity cutting.

The spindle of the machine tool adopts a thin oil lubrication method, the lubricating oil is circulated externally, and the spindle bearing has a good fan heat effect; or the spindle unit structure. The machine tool guide rail is lubricated by an electric oil pump.

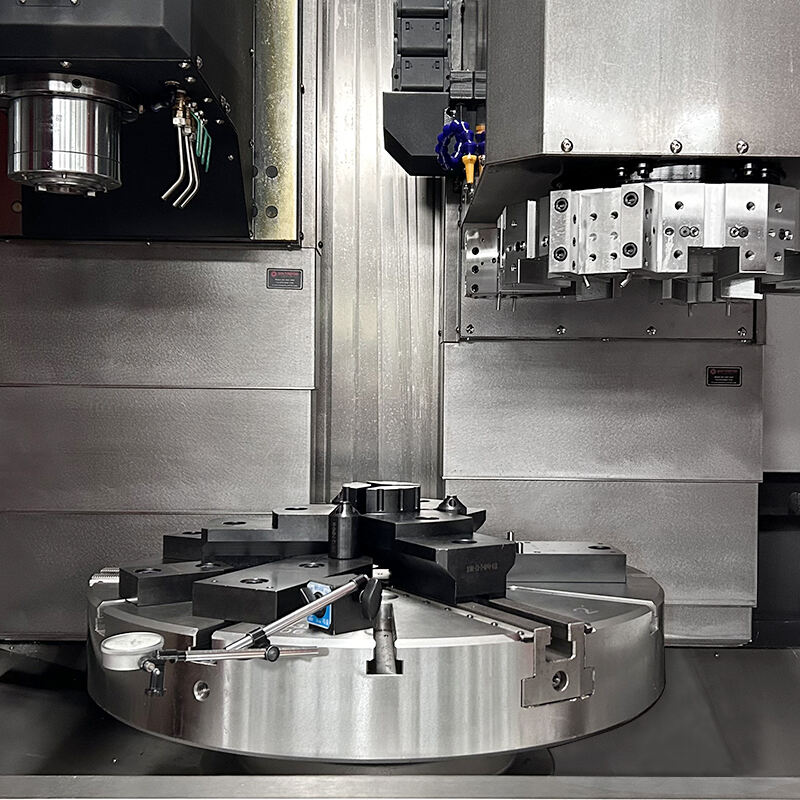

The machine tool is equipped with a hydraulic chuck with high positioning accuracy and strong clamping force.

Specification |

Main technical parameters |

|

VTC1010 |

Maximum rotation diameter |

mm |

1000 |

|

Maximum turning diameter |

mm |

850 |

|

Vertical moving distance of tool holder |

mm |

200-1200 (Distance between the lower end of the cutter head and the chuck surface) |

|

Horizontal moving distance of tool holder |

mm |

-50-500 (distance between inner hole turning tool and turning spindle center) |

|

Drilling range |

Maximum drilling diameter |

mm |

40 (U drill, distribution diameter less than 250) |

Vertical moving distance of drilling spindle |

mm |

150-1150 (Distance between the lower end of the drill shaft and the chuck surface) |

|

Horizontal moving distance of drilling spindle |

mm |

-50-500 (Drilling spindle center to turning spindle center distance) |

|

Turning Spindle Unit |

Turning spindle model |

/ |

A2-11 |

Turning spindle bearing arrangement |

/ |

NN3036 180X280X74 double row cylindrical roller bearings |

|

/ |

NN3030 150X225X56 double row cylindrical roller bearings |

||

/ |

234436 180X280X120 double direction thrust angular contact ball bearing |

||

Turning spindle speed range |

rpm |

20-800(1:2.5 speed ratio) |

|

Turning spindle motor |

kW |

22/30 |

|

Drilling spindle unit (center water outlet) |

Drilling spindle model |

/ |

BT40-150 |

Drilling spindle speed range |

rpm |

50-7000(1:1 speed ratio) |

|

Drilling spindle motor |

kW |

11/15 |

|

Tool holder and chuck |

8-station turret |

/ |

LS-250H |

Turret center height |

mm |

125 |

|

Turret side distance |

mm |

420 |

|

Four-jaw manual chuck |

mm |

800 |

|

Tool magazine (drill spindle, BT40) |

Disc tool magazine |

/ |

16把 |

Max tool diameter/length |

mm |

78/300 |

|

Maximum tool weight |

Kg |

8 |

|

Feed |

X1/X2 axis rapid feed speed |

m/min |

15m/min |

Z1/Z2 axis rapid feed speed |

m/min |

15m/min |

|

Cutting feed speed |

m/min |

0.1-5000mm/min |

|

X1/X2 axis motor power, torque |

kw/nm |

2.8 /18 |

|

Z1/Z2 axis motor power, torque |

kw/nm |

3.5 /22 Holding brake |

|

Optical machine dimensions and weight |

Machine weight (approx.) |

kg |

≈12800 |

Machine tool dimensions |

mm+ |

3500×2950×4200 |

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

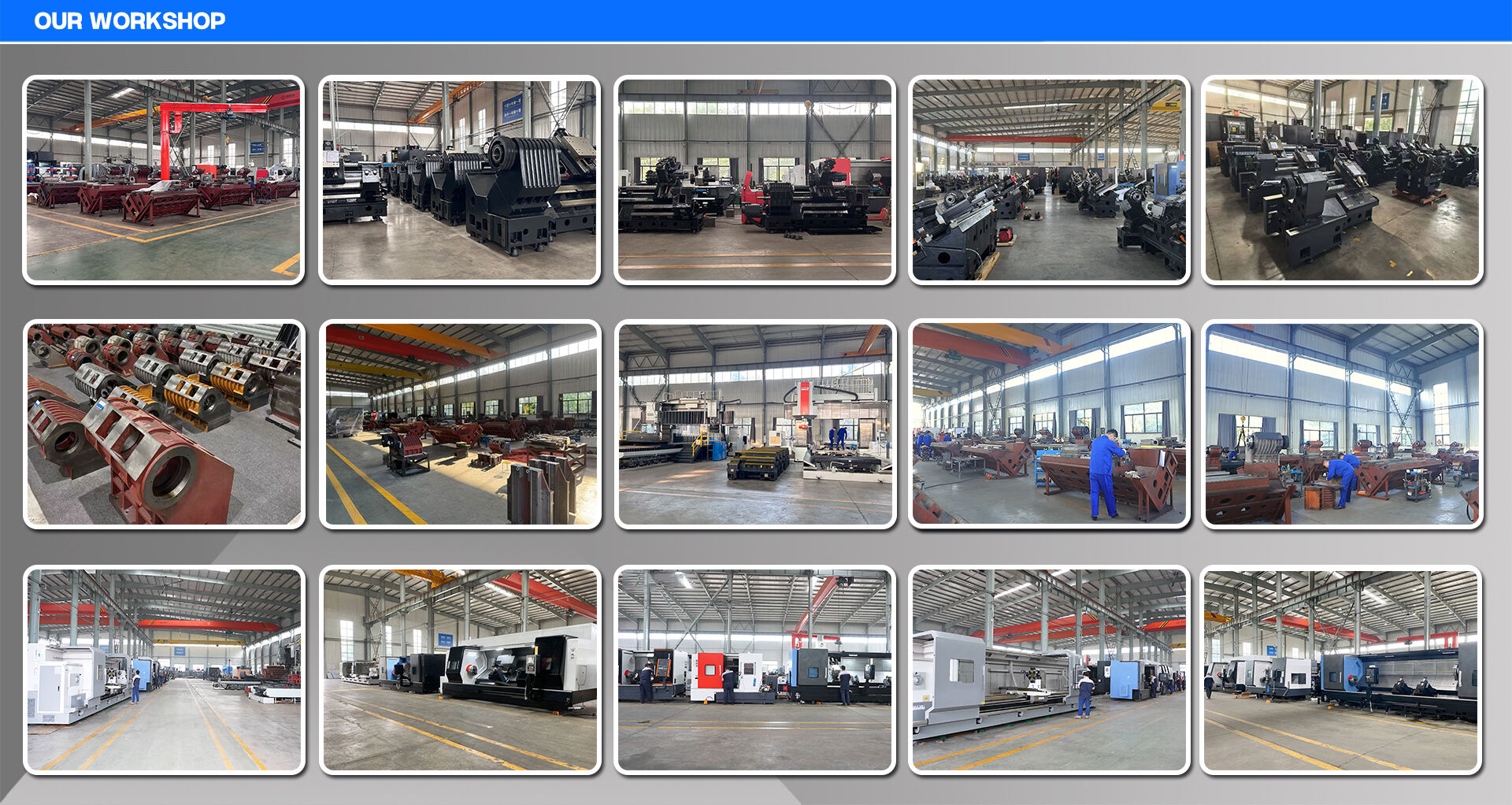

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

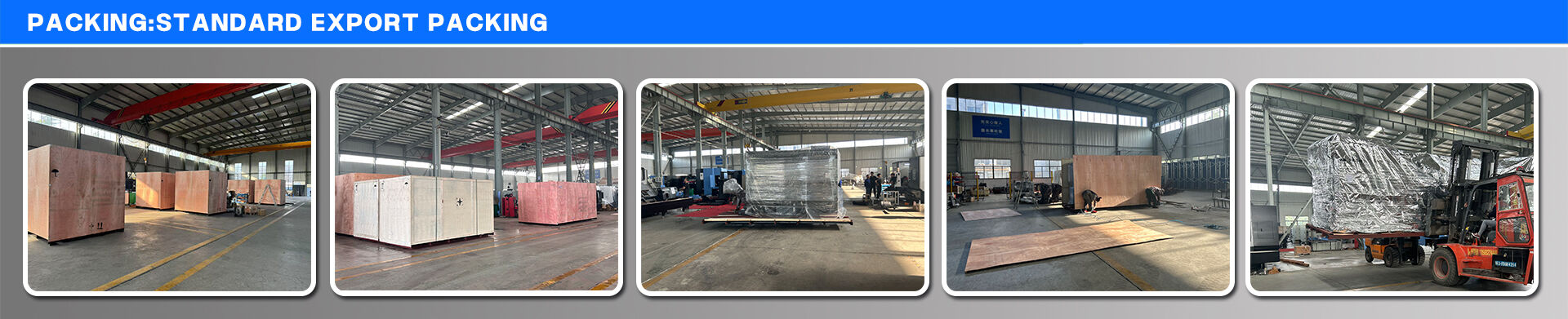

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.