Onko kaksikiila-CNC-jyrsin tehokkaampi kuin yksikiila-CNC-jyrsin - Dongs Solutions

Yksinkertaisesti sanottuna kaksikärkisen CNC-jyrsimen ydineta on muuttaa "peräkkäinen koneenpito" "rinnakkaiseksi koneenpidoksi", mikä vähentää merkittävästi tuotantosyklin kestoa.

Tehokkuus

Yksikärkinen CNC-jyrsin

Työtila: Yksi kärki kuljettaa kaikki työkalut. Koneenpidon aikana kärki liikkuu määrättyyn asemaan, käyttää yhtä työkalua suorittaakseen prosessin (esim. ulkohalkaisijan sorvauksen), vetäytyy sitten takaisin, vaihtaa työkalun ja siirtyy seuraavaan prosessiin (esim. uran poraamiseen). Kaikki prosessit on suoritettava peräkkäin .

Erityisesti monimutkaisten osien koneenpidossa suuri määrä aikaa kuluu työkalun tyhjäkäyntiin ja työkalunvaihtoon .

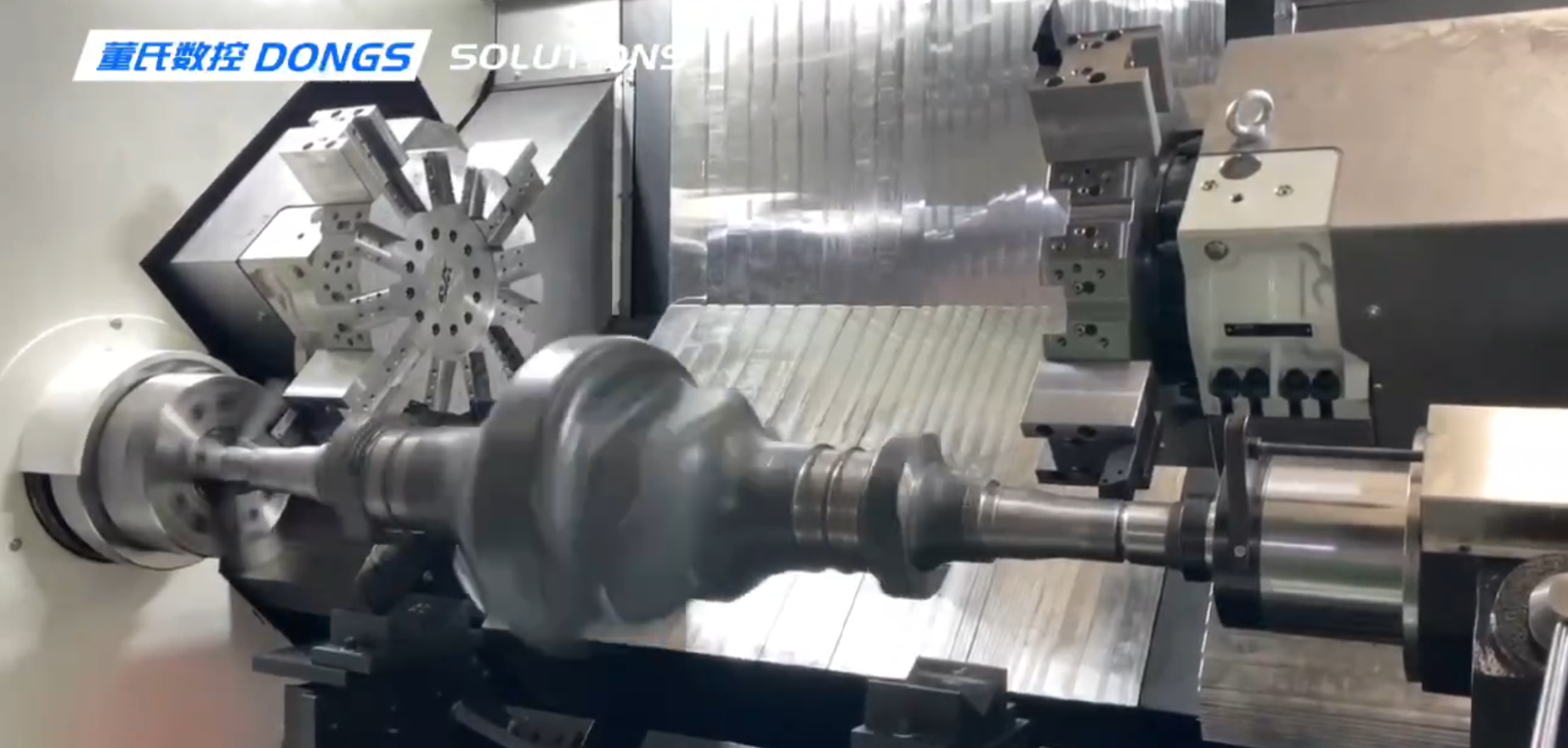

Työtila: Kaksi riippumatonta kärkeä (yleensä nimeltä T1 ja T2) voivat työskennellä samanaikaisesti . Kumpikin kärki on varustettu omalla erillään olevalla työkalusarjalla.

Työnjakaminen ja yhteistyö: Kun turretti T1 koneistaa osan etupään, turretti T2 voi samanaikaisesti koneistaa osan takapään.

Vähentynyt tyhjäkäyntiliike: Kahden turretin liikealueet on optimoitu, mikä johtaa lyhyempiin liikeratoihin ja välttää yhden turretin pitkän matkan edestakaisen liikkumisen.

Lähes nollaan supistunut työkaluvaihtoaika: Koska työkalut on jaettu kahteen turrettiin , kummankin turretin hallittavien työkalujen määrä on pienentynyt, mikä vähentää huomattavasti työkaluvaihtojen taajuutta ja odotusaikoja.

Keskeiset skenaariot, joissa kaksiturrettilatamekon koneet saavuttavat korkean tehokkuuden

Osat, jotka vaativat kaksipäisen koneistuksen: Esimerkiksi akselityyppisen osan käsittelyssä yksittäispyörällinen kone joutuu ensin valmistelemaan pään A, minkä jälkeen osa on kiinnitettävä uudelleen pään B käsittelyä varten. Kaksipyörällinen kone voi käsitellä pää A etupyörällä ja pää B samanaikaisesti takapyörällä yhdessä asennossa , säästäen näin aikaa toistokiinnitykselle ja työkalujen vaihtamiselle samalla taataen erittäin korkean keskittymän.

Monimutkaisia prosesseja vaativat osat, jotka edellyttävät lukuisia työkaluja: Kun osa vaatii useita eri toimenpiteitä, kuten sorvausta, porausta, jyrsintää ja kierteitystä, yksittäispyörällinen kone kärsii alhaisesta tehokkuudesta useiden työkaluvaihtojen vuoksi. Kaksipyörällinen kone voi kaksoiskupolinen CNC-kaivin jakaa työkalut erikseen

Huolimatta niiden erinomaisesta tehokkuudesta, kaksipyörälliset CNC-sorvit eivät ole tarpeellisia kaikille osille . Rakenteellisesti yksinkertaisille osille, joissa on hyvin vähän käsittelyvaiheita, kaksipyöräisen asettelun tehokkuusedu ei ehkä tule voimaan. Vasta sopivissa käsittelyskenaarioissa kaksipyöräinen CNC-sorvi tarjoaa huomattavasti korkeamman työtehokkuuden kuin yksittäispyörällinen CNC-sorvi.

DONGS CNC tarjoaa erilaisia ammattipalveluita myynnin edistämiseen liittyvistä kysymyksistä asiakastukeen. Olemme sitoutuneet tarjoamaan jokaiselle asiakkaalle parhaiten sopivan ratkaisun ja auttamaan heitä menestymään kovassa markkinakilpailussa ammattimaisen valintaneuvonnan ja jatkuvan palvelutuen avulla.