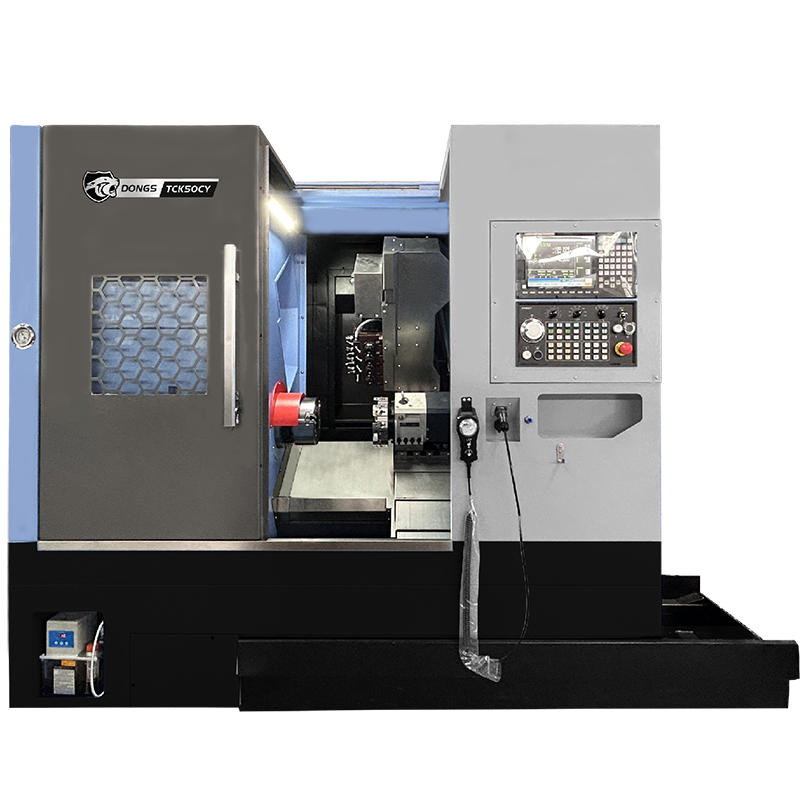

5 axis cnc

- Machine tool manufacturers

- Precision machine tool manufacturers

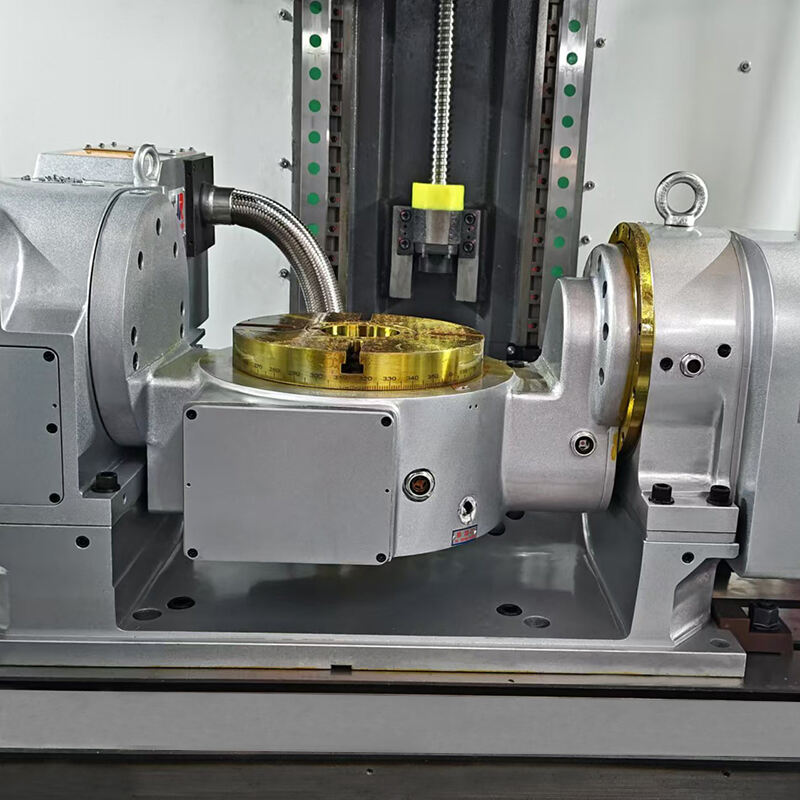

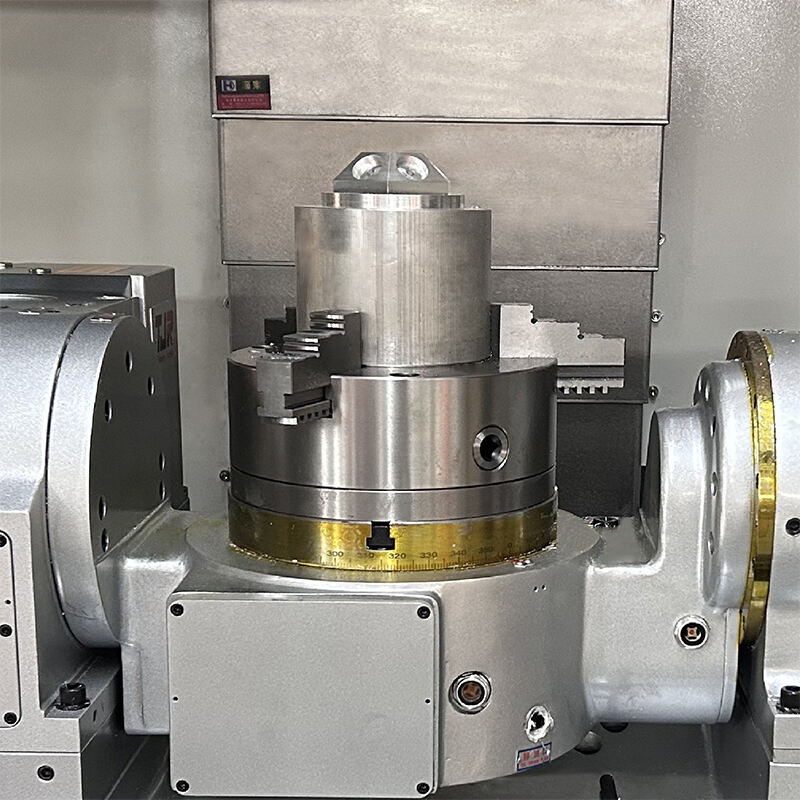

- 5-axis CNC turntable

- High quality resin sand cast iron

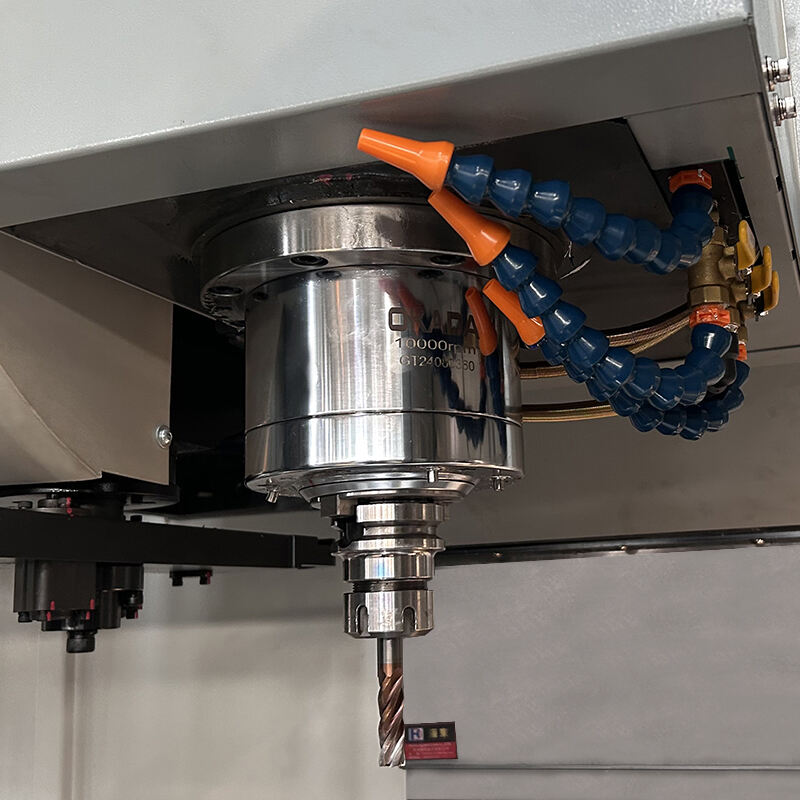

- Taiwan main axis

- Taiwan ball screw and lock nut

- Taiwan booster cylinder

- Automatic lubrication system

Introduction

Main features of CNC milling machine:

(1)Three sets of linear guide rails are configured, which have excellent seismic resistance, high positioning accuracy, low noise operation and low resistance characteristics, achieving high-speed and stable movement and ensuring accurate closed-loop control of the processing trajectory;

(2)Key load-bearing components are cast by special cast iron process, and the material is selected from Meehanite grade high-quality cast iron. The internal stress is eliminated through aging treatment to ensure stable mechanical properties throughout the life cycle of the equipment;

(3)The components are topologically optimized, the optimal stress distribution model is constructed through computer-aided engineering calculations, and the grid-shaped reinforcement rib layout is scientifically designed to significantly improve the overall structural rigidity;

(4)The innovative design of the box-type composite foundation platform and the portal column collaborative structure, the implementation of the extended heavy-duty support solution on the work surface, double the load-bearing contact area, and build a multiple safety guarantee system under heavy-duty processing conditions;

(5)The spindle unit adopts a multi-directional truss support structure, optimizes the column contact surface through the golden ratio, forms a three-dimensional reinforcement system, and completely eliminates vibration transmission during the cutting process;

(6)The intelligent protection system integrates a multi-level buffer module, absorbs abnormal impact energy through a combination of hydraulic damping and elastic elements, minimizes mechanical damage caused by misoperation, and maintains the initial accuracy parameters of the equipment;

(7)The process lubricant and coolant are independently recovered and processed through a physical isolation device to avoid liquid performance degradation caused by cross contamination and ensure a continuous and stable processing environment;

(8) The machine tool adopts Taiwan's high-precision, high-rigidity, and high-precision spindles. The belt-type spindles have strong rigidity and high reliability, and the direct-drive spindles are high-speed, efficient, high-precision, low-noise, and low-vibration, fully meeting user needs;

Main applications of CNC milling machine

Automotive Manufacturing: Ideal for precision machining of engine parts, gearbox housings, and suspension components.

Aerospace Components: Perfect for high-precision manufacturing of complex parts like turbine blades and brackets.

Medical Device Manufacturing: Used to create intricate and precise parts for medical tools, implants, and diagnostic devices.

Mold Making: Excellent for producing high-precision molds for injection molding or die casting.

Tooling and Fixture Production: Suitable for manufacturing high-quality jigs, fixtures, and tooling used in various industries.

Electronics Industry: Used for the precise machining of components such as connectors, enclosures, and housings.

General Precision Engineering: Versatile enough for a wide range of industries requiring tight tolerances and complex geometries.

| Specifications | Unit | VMC1160 |

| X-axis travel (left and right) | mm | 1100 |

| Y-axis travel (front and rear) | mm | 600 |

| Z-axis travel (up and down) | mm | 600 |

| Distance from nose end of main shaft to working surface | mm | 120-720 |

| Distance from spindle center to column rail surface | mm | 650 |

| Table size (x-axis direction) | mm | 1200 |

| Table size (Y-axis direction) | mm | 600 |

| T-groove of worktable | mm | 18X5X100 |

| Maximum load of worktable | kg | 800 |

| Spindle speed (belt drive) | rpm | 12000 |

| Recommended horsepower of spindle | kW | 11--15 |

| Taper of main shaft inner hole | - | BT40-150 |

| G00 rapid feed (X/Y/Z axis) | m/min | 36/36/36 |

| G01 cutting feed | mm/min | 1-8000 |

| Servo motor specifications | kW | 3 X 3 X 3 |

| Magazine capacity | ATC | Arm 24 |

| Weight approximately | KG | 6300 |

| Dimensions | m | 4420*2280*2550 |

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

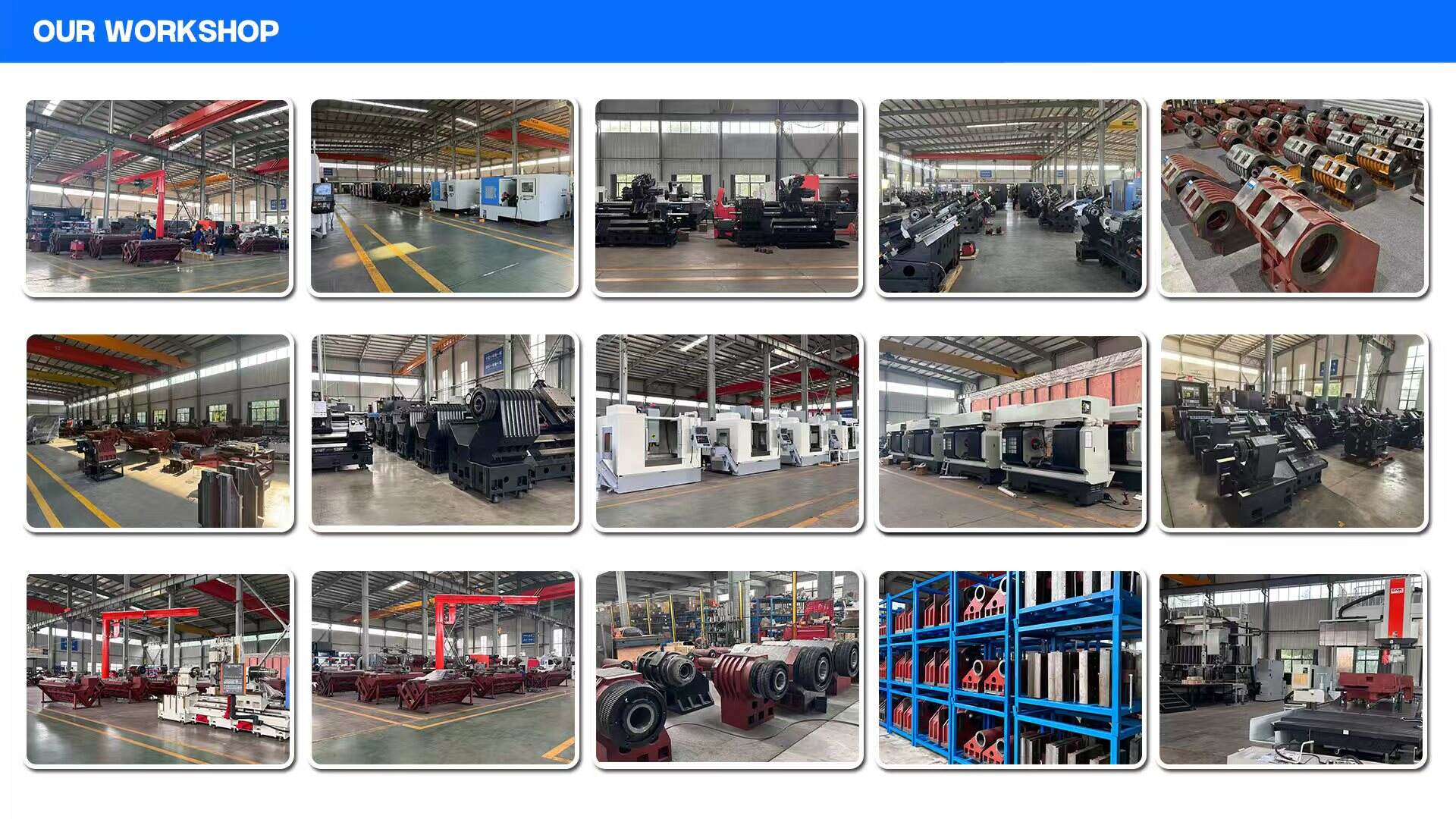

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.